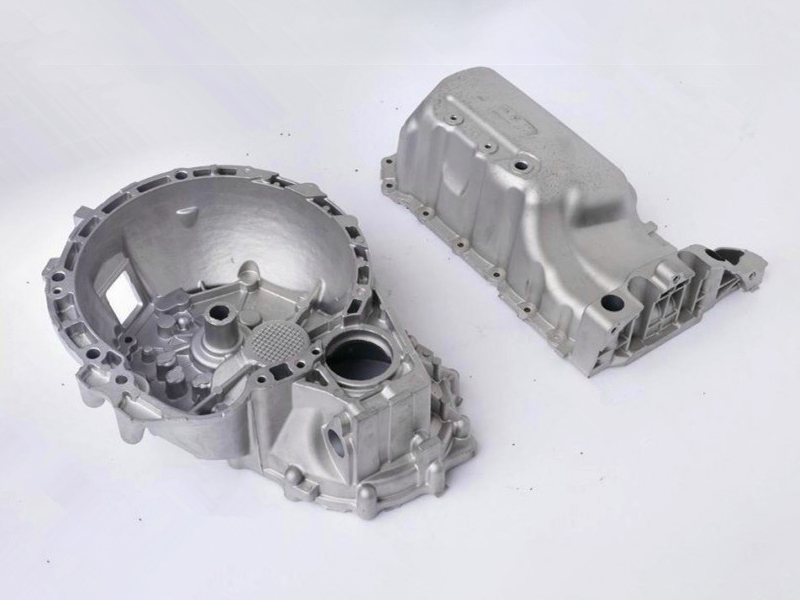

Zinc Die Casting Services

Exploring the Pinnacle of Zinc Die Casting Manufacturing Capability

As a seasoned zinc die casting manufacturer with 18 years of experience rooted in China, we pride ourselves on delivering superior-quality parts to a global clientele. Our expertise is not confined to mere production; we offer a comprehensive one-stop solution that encompasses rapid prototyping, product mold development, die casting, and surface treatment. Our commitment to excellence extends to providing clients with a full spectrum of customization options for die casting parts, ensuring that the final products align perfectly with your specific requirements.

Our Manufacturing Edge: One-Stop Production and Customization

Our facility is a hub of innovation and precision, where ideas transition seamlessly from conception to reality. The journey begins with rapid prototyping, a process that allows us to swiftly create accurate models of your parts, enabling thorough evaluation before mass production. This step is crucial for identifying potential design issues and ensuring that the final product meets your expectations in terms of form and function.

Once the prototype receives your approval, we proceed to product mold development. Our skilled engineers craft molds with meticulous attention to detail, ensuring that each cavity reflects the precise dimensions and contours of the intended part. This attention to detail is a cornerstone of our ability to consistently produce high-quality castings.

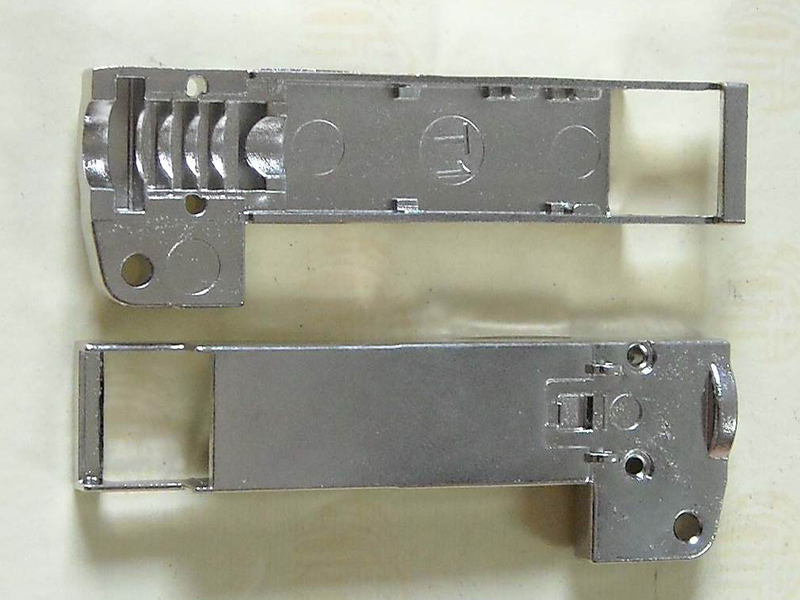

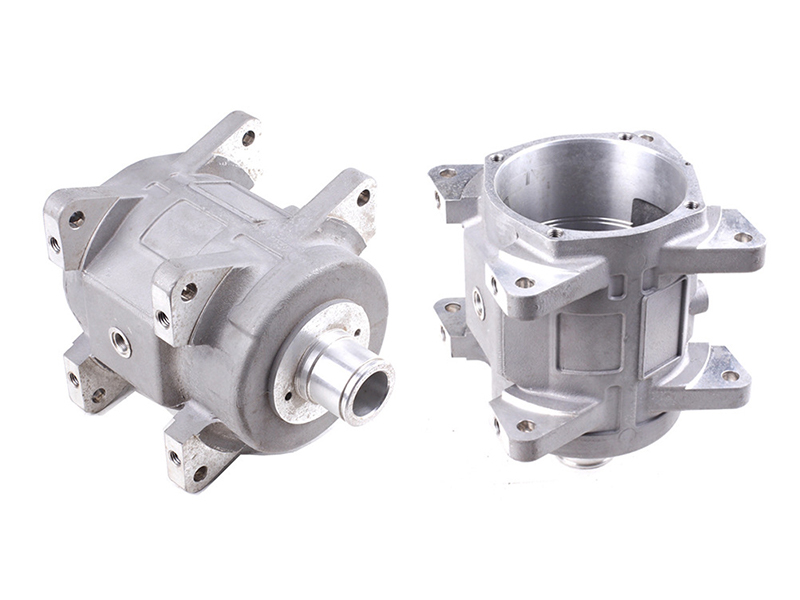

The die-casting process itself is where our technical prowess truly shines. Zinc, known for its durability and excellent casting properties, is melted and injected into the custom mold under high pressure. This method allows us to capture intricate details and maintain tight tolerances, resulting in parts that meet the most stringent quality standards.

Unveiling the Zinc Die Casting Material Portfolio: A Guide to Processing Capacity

When it comes to zinc die casting, selecting the right material is crucial for achieving the desired properties and performance of the final parts. As a distinguished zinc die casting manufacturer, we offer a diverse range of zinc alloys, each with unique features that cater to different purposes. Below is an overview of the zinc materials we process, along with their codes, features, and typical applications, ensuring that our clients receive parts that are not only high in quality but also perfectly suited to their specific needs.

Zinc Die Casting Material Information:

Material: Zinc (YX040 - NO.3)

Features:

Low melting point, contributing to a long mold life.

Excellent casting performance, allowing for the creation of particularly complex, thin-walled parts.

Low propensity to stick to the mold, paired with commendable room temperature performance.

Good welding and electroplating properties.

High density yet exhibits poor corrosion resistance.

Purpose: Ideal for dimensionally stable, high-precision parts where complexity and thin walls are required.

Material: Zinc (YX041 - NO.5)

Features: Medium strength alloy, suitable for creating both chrome and non-chrome parts.

Purpose: Frequently used for parts that require a balance of strength and ductility, often with a decorative or protective finish.

Material: Zinc (YX043 - NO.2)

Features: High-strength alloy, apt for crafting various small, thin-walled parts intended for chrome plating.

To complete the manufacturing cycle, we offer a variety of surface treatments to enhance the appearance and performance of the zinc cast parts. Options such as powder coating, painting, plating, and anodizing not only improve the aesthetic appeal but also provide additional protection against corrosion, wear, and environmental factors.

Custom Solutions Tailored to Your Needs

Understanding that each client has unique needs, we have honed our craft to offer fully customizable die casting solutions. Our collaborative approach involves working closely with you to understand your project's specific requirements, from material selection to final specifications. We leverage our extensive experience to advise on design optimizations that can reduce costs, improve functionality, and streamline production.

With a commitment to quality and customer satisfaction, we employ rigorous quality control measures throughout the manufacturing process. Our factory adheres to international standards, ensuring that every part we produce meets both our high internal benchmarks and your exacting expectations.

As we continue to serve customers around the world, our dedication to innovation, quality, and service remains steadfast. Whether you require small-scale production or large-volume runs, we are equipped to deliver zinc die casting parts that truly embody the essence of your vision. Connect with us to explore how our manufacturing capability can bring unparalleled value to your next project.

Purpose: Best suited for parts that demand superior strength while maintaining intricate shapes and fine details, often finished with chrome plating for aesthetic and protective qualities.

Material: Zinc (YX081 - ZA-8)

Features: High-strength alloy designed for producing hard parts.

Purpose: Utilized in applications where durability and wear resistance are paramount, such as gears, connectors, and complex mechanical components.

Each of these materials is chosen for its ability to fulfill the stringent requirements of different industries and applications. We understand that the properties of the alloy, such as melting point, strength, and corrosion resistance, play a vital role in the performance of the cast parts. That's why we meticulously select the appropriate zinc alloy based on the specific characteristics needed for your project.

At our facility, we combine these high-quality materials with advanced zinc die casting techniques to manufacture parts that not only meet but exceed expectations. From automotive components to precision electronic housing, our processing capacity is geared towards delivering results that align with your project's unique demands.

By offering a range of zinc alloys, each with its own set of advantages, we empower our clients to make informed decisions that optimize the functionality and longevity of their die-cast products. Partner with us to capitalize on our extensive material knowledge and processing expertise, ensuring that your zinc die casting requirements are met with the highest level of precision and quality.

Why Choose LK tools Die Casting for Custom Zinc Alloy Die Casting Services

When it comes to manufacturing custom zinc alloy die casting parts, the choice of your production partner can significantly impact the quality, efficiency, and success of your project. Huayin Die Casting stands out as an exceptional choice for several compelling reasons.

Strong Engineering Team Support

At Huayin Die Casting, we are proud to have a robust team of over 20 engineers, each boasting over a decade of experience in the industry. This wealth of knowledge and expertise enables us to provide professional technical support around the clock—7 days a week, 24 hours a day. Our engineers are adept at handling complex design challenges and can offer insightful solutions to meet your die casting needs effectively.

Strict Quality Control

Quality is at the core of everything we do at Huayin Die Casting. As an ISO-certified company, we maintain a stringent quality control regime, overseen by more than 20 seasoned quality engineers. Our facility is equipped with state-of-the-art testing equipment, ensuring that every aspect of production, from prototyping to final zinc die casting parts, adheres to rigorous manufacturing standards. Our commitment to quality means we deliver prototypes and parts that consistently exceed expectations.

FAQs about LK toools Zinc Alloy Die Casting Services

When considering Huayin Die Casting for your zinc alloy die casting needs, you may have several questions about our capabilities and services. We've compiled a list of frequently asked questions to provide you with detailed insights into our processes and offerings.

What is the tonnage range of your zinc alloy die casting machines?

Our facility is equipped with a variety of zinc alloy die casting machines to accommodate different project sizes and requirements. Our machines have tonnages of 88T, 180T, 280T, and 400T. This range allows us to efficiently produce zinc die casting parts of varying sizes and complexities with precision and quality.

How long does it take to create a mold for zinc alloy die casting?

At Huayin Die Casting, we have an in-house mold room, which enables us to manage the mold development process efficiently. Typically, the mold creation cycle for zinc alloy die casting takes about 10-15 days. This timeframe can vary depending on the complexity and size of the mold.

What is the maximum size for zinc alloy die casting parts that you can produce?

For custom zinc alloy die casting, we can manufacture parts up to a maximum of 400MM in size. This

One-Stop Solution

We understand the value of convenience and efficiency in the production process. Huayin Die Casting offers a comprehensive one-stop production customization service that incorporates rapid prototyping, mold creation, die casting, CNC machining, and surface treatment. This streamlined approach saves you time and simplifies the logistics of bringing your design from concept to reality, all under one roof.

Efficient After-sales Service

Our dedication to our clients doesn't end with the delivery of parts. Huayin Die Casting provides a 30-day quality assurance period to ensure your complete satisfaction with our products. In the event of any concerns, our responsive after-sales service team is available 7 * 24 hours to provide prompt assistance. We are committed to resolving issues within 1-3 working days, ensuring that any potential challenges are addressed quickly and effectively.

Choosing Huayin Die Casting means partnering with a company that places a high value on engineering expertise, quality, comprehensive services, and responsive customer care. Let us help you navigate the complexities of zinc alloy die casting with the assurance of superior service and exceptional results. Contact us today to discuss how we can support your custom die casting project.

limitation ensures that we can maintain the highest quality and accuracy for each part we produce, while still offering a significant range of sizes to meet most project requirements.

What types of surface treatments can you perform on zinc alloy die casting parts?

We offer a variety of surface treatments to enhance the appearance and functionality of our zinc alloy die casting parts. These treatments include:

Electroplating: Provides a decorative finish and adds corrosion resistance.

Painting: Offers a wide range of colors and can improve resistance to wear and environmental factors.

Powder Coating: Creates a durable and protective layer that is thicker than regular paint.

Electrophoresis: Results in a uniform finish that is resistant to corrosion, chipping, and fading.

Passivation: Increases the thickness of the natural oxide layer on the metal surface, improving resistance to corrosion.

Our selection of surface treatments allows us to tailor the finish of each part to meet the specific needs of your application, whether it's for aesthetic purposes or to enhance durability.

If you have further questions or would like more information about our zinc alloy die casting services, please do not hesitate to contact us. Our team of experts is here to provide you with the support and guidance necessary to make your project a success.