Rapid Prototyping Services

LK tools: Your Partner for World-Class Rapid Prototyping Services

Stay at the forefront of product innovation with LK tools's rapid prototyping services. By subscribing to our newsletter, you'll gain access to a wealth of knowledge on the latest prototyping technologies, techniques, and industry trends.

Subscribe for the Latest in Rapid Prototyping:

Enter Your Name: We invite you to join our community and receive personalized updates.

Enter Your Email: Stay informed with regular newsletters sent straight to your inbox, detailing breakthroughs in rapid prototyping.

Enter Your Phone & Whatsapp: For direct communication or mobile updates, please include your phone number and WhatsApp details.

Your Messages: Share any specific prototyping interests or questions you have, and we'll tailor our content to your needs.

Click "SEND" to subscribe and embark on a journey of manufacturing excellence with us.

LK tools's Prototyping Expertise:

Rapid CNC Machining: Precision Prototyping for Diverse Industries

At LK tools, rapid CNC machining stands as a cornerstone of our prototyping methods, particularly favored for metal prototypes. With a decade of experience in various CNC prototype manufacturing, we serve industries ranging from automotive and electronics to energy and medical.

The Advantages of Rapid CNC Machining:

Precision: Our CNC machining prototypes are synonymous with precision, ensuring that every detail of your design is accurately realized.

Surface Finishes: Expect the highest quality surface finishes, contributing to the functionality and aesthetic appeal of your prototypes.

We pride ourselves on delivering rapid prototyping services that are synonymous with quality, punctuality, and cost-effectiveness.

Our engineering team harnesses cutting-edge prototyping technologies and brings extensive experience to every project.

Our prototyping centers are fully equipped to meet the diverse needs of our global clientele, addressing specific requirements, tight deadlines, and unique challenges.

Understanding Rapid Prototyping:

Rapid prototyping is a specialized technique that converts 3D design concepts into high-quality physical models, serving as a critical tool for design refinement and engineering validation.

This approach is both time-efficient and cost-effective, eliminating the need for heavy investment in hard tooling equipment.

The essence of rapid prototyping lies in its ability to quickly produce tangible parts for design validation and capturing market opportunities.

With LK tools, you can swiftly turn your concepts into reality, leveraging our expertise and rapid prototyping technologies. Let us help you accelerate your product development and achieve success in the market. Contact us today to learn more about our rapid prototyping services.

Material Versatility: There is no limit to the selection of materials available, allowing for a wide range of prototyping applications.

Efficiency Considerations:

Although CNC machining requires time for preparation and setup, its benefits for high precision and metal prototypes are unmatched. We strategically utilize CNC machining to cater to projects that demand the utmost accuracy and quality.

Rapid CNC machining by LK tools is the perfect solution for clients who require quick turnaround times without compromising on precision. Contact us to learn more about how our rapid CNC machining services can elevate your prototype development.

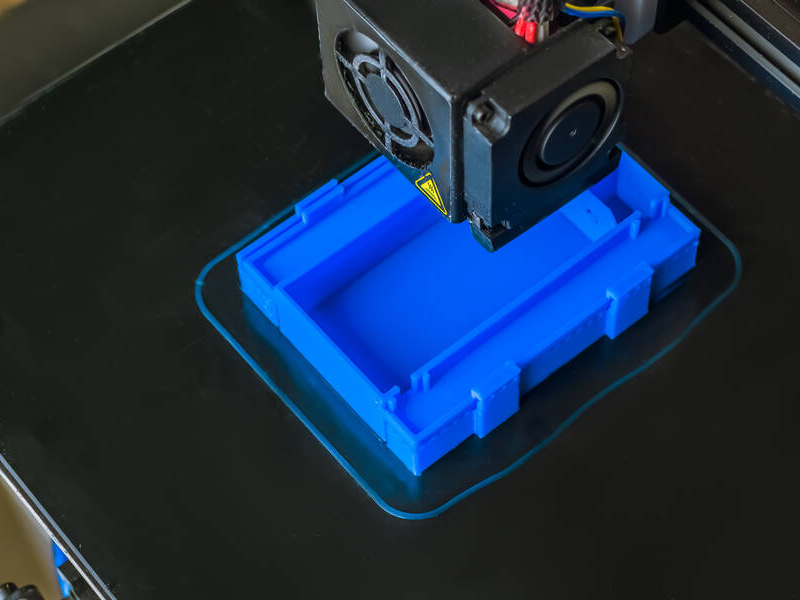

Harnessing Rapid 3D Printing for Advanced Prototyping

As an industry pioneer, we understand the unique benefits each 3D printing technology brings to different stages of rapid prototyping.

SLA Prototyping:

Utilizes liquid plastic material to create prototypes with excellent surface finishes, making it ideal for projects requiring high aesthetic quality.

SLS Prototyping:

Similar to SLA in terms of precision, SLS prototyping requires a powdered material, often resulting in prototypes with enhanced strength and functionality.

FDM Prototyping:

Accelerating Product Development with Rapid Sheet Metal Fabrication

Rapid sheet metal prototyping is a key service offered by LK tools, utilizing a subtractive manufacturing process to form parts with exceptional precision and durability. Here's an overview of our rapid sheet metal fabrication capabilities:

Sheet Metal Fabrication Process:

We transform thin metal sheets into intricate parts through methods such as cutting, bending, folding, stamping, and assembling.

These parts are known for their precision and robustness, making them ideal for a variety of end-use applications, including enclosures, brackets, and chassis.

Cost Efficiency & Production Volume:

Recognized as the most cost-effective and quickest method within 3D printing technology. FDM can produce a complete prototype part within a single day, offering a swift solution for initial design validations.

Material Considerations:

While 3D printing offers unparalleled speed in prototyping, it's important to note that the materials used can be costly compared to traditional manufacturing processes.

Rapid 3D printing is an invaluable tool for accelerating product development and prototyping efforts. By selecting the most suitable 3D printing method based on your project's requirements, you can efficiently progress from concept to prototype with the confidence of achieving the desired results.

Our sheet metal fabrication services are competitively priced, offering economical solutions for small volume prototype production.

We also provide significant cost savings for large volume production, making it a viable option for projects at any scale.

Precision Services by LK tools:

LK tools specializes in high-precision cutting, bending, punching, and welding of sheet metal.

We also offer assembly services to deliver complete, ready-to-use components.

Rapid sheet metal fabrication is an invaluable solution for engineers and product developers who require sturdy, precise parts for their applications. Whether you need prototypes or are gearing up for large-scale production, LK tools is equipped to deliver high-quality sheet metal parts that meet your exact specifications. Contact us to start your next sheet metal project and experience the efficiency and quality of our services.

Rapid Vacuum Casting: Efficient and Cost-Effective Prototyping

Our sheet metal fabrication services are competitively priced, offering economical solutions for small volume prototype production.

Vacuum casting, known as urethane casting, is an economical and efficient method for producing small quantities of high-fidelity plastic parts that closely replicate the properties of final production items.

How Vacuum Casting Works:

Molds for vacuum casting are typically fashioned from silicone rubber, with the master pattern created through CNC machining or SLA (Stereolithography) parts.

These silicone molds are adept at capturing even the most intricate details and textures from the master pattern, ensuring each cast part is consistent in quality.

Benefits of Vacuum Casting:

It produces parts that exhibit similar mechanical properties, wall thickness, color, and surface textures to those found in items manufactured at scale.

Vacuum casting is the go-to choice for product developers who need a small batch of parts with production-level quality. Whether you're in the prototyping stage or require a limited production run, our rapid vacuum casting services can deliver parts that meet your specifications with the look and feel of mass-produced products.