CNC Machining PEEK

The Advantages of CNC Machining in Crafting High-Quality PEEK Plastic Parts

PEEK, or Polyether ether ketone, is a high-performance engineering thermoplastic renowned for its outstanding mechanical and chemical resistance properties, which remain consistent even at elevated temperatures. This makes CNC PEEK machining services an excellent choice for fabricating high-quality components that require electrical and thermal insulation, along with numerous other benefits.

PEEK's robustness, characterized by its great strength, wear resistance, abrasion resistance, and chemical resilience, renders it an optimal material for various challenging environments. It is particularly favored in industries such as aerospace, automotive, chemical processing, fluid handling, and applications that operate under high-temperature conditions.

Expert PEEK CNC Machining Services for Precision Plastic Parts

At LK tools, we specialize in plastic CNC machining with an extensive track record in working with a diverse array of plastic materials and PEEK grades. As one of China's leading plastics and composite machining companies, our proficiency with multi-axis CNC PEEK machining allows us to tackle complex projects with efficiency and pinpoint accuracy, meeting even the most stringent geometrical and tolerance demands.

We pride ourselves on producing CNC machined PEEK parts that are perfectly tailored to our customers' specifications or based on CAD drawings they provide. Our team of engineers and designers is dedicated to optimizing your designs to achieve the best possible results while minimizing costs.

Whether you're looking to develop PEEK (Polyether ether ketone) products or prototypes, we're eager to discuss every detail of your project to ensure it aligns with your vision. We maintain consistent communication throughout the production cycle of your PEEK machined parts, ensuring transparency and collaboration from start to finish.

Our PEEK CNC machining services are designed to minimize manufacturing errors and maximize productivity, delivering exceptional quality and precision in every component. Trust LK tools to bring your PEEK machining projects to life with the skill and attention to detail that only decades of experience can provide.

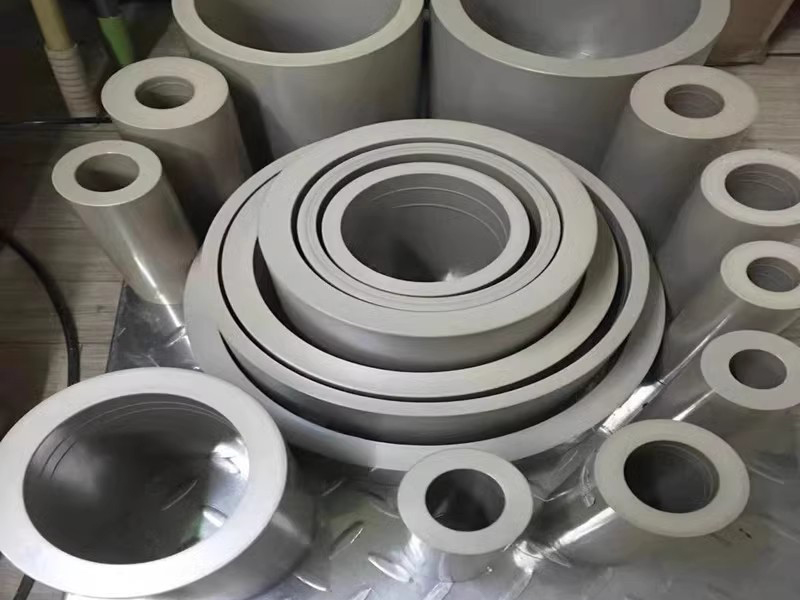

This semicrystalline thermoplastic polymer is commonly supplied in bar and rod forms, making it well-suited for a range of CNC machining and cutting operations. Techniques such as sawing, drilling, milling, and turning can be precisely executed on PEEK material to create intricate parts with high precision.

PEEK plastic can also be found in specialized versions that enhance its inherent properties, including glass-fiber and carbon fiber reinforced grades for increased strength and stiffness, bearing grade for improved wear resistance, and medical grade for biocompatibility and sterilization resilience.

For those seeking to leverage the exceptional qualities of PEEK in their parts and products, CNC machining offers a reliable and efficient manufacturing solution. With the ability to work with various grades of PEEK, CNC machining ensures that the finished components meet the stringent requirements of the most demanding applications.

Exploring the Versatile Applications of CNC Machined PEEK Parts

PEEK (Polyether ether ketone) is an exceptional engineering plastic renowned for its superior performance and versatility. Its remarkable properties give it a competitive edge over many other engineering plastics, making it an ideal choice for critical applications in sectors such as aerospace, automotive manufacturing, electronics and electrical, medical, and food processing.

PEEK's high-temperature resistance, self-lubrication, ease of processing, and impressive mechanical strength enable it to be fashioned into a variety of mechanical components. In the automotive industry, it is used to make durable gears, oil screens, and shift start discs. Its purity and resistance to contamination make it perfect for pipelines, valves, and pumps used in ultrapure water systems.

In the demanding world of aerospace, PEEK is utilized for crafting engine parts that can endure extreme conditions. Its resilience is also harnessed in household appliances, such as automatic washing machine runners, and in medical devices where safety and reliability are paramount.

Moreover, PEEK maintains excellent electrical insulation, even in harsh environments with high temperatures, voltages, and humidity. This quality has led to its increased adoption in the electronic information sector, making it the second-largest application field for PEEK resin.

Another notable use of PEEK is in the medical field, where its lightweight, non-toxic, and corrosion-resistant nature, along with its compatibility with human tissue, makes it a promising material for bone replacement and other biomedical applications.

With its exceptional physical and mechanical properties, CNC machined PEEK parts are progressively replacing traditional materials like metals and ceramics in specialized fields, offering innovative solutions that meet the evolving demands of modern industries.

The Benefits of Selecting LK tools for Your PEEK CNC Machining Needs

When it comes to crafting precision PEEK parts, LK tools stands at the forefront of the CNC machining industry. Here's why our PEEK CNC machining services are the top choice for clients seeking quality, precision, and efficiency:

Cutting-Edge Technologies: Our advanced machining technologies and equipment guarantee that every part produced is accurate and consistent, ensuring repeatable results across all orders.

Exceptional Precision: We are capable of meeting tight tolerances and delivering high precision on every component. Custom specifications are meticulously adhered to, fulfilling the unique requirements of each client.

Material Handling Expertise: Our skilled technicians are adept at handling PEEK material to minimize internal stress, which is crucial in preventing cracks and ensuring the integrity of the final product.

Quality Assurance: We conduct on-site inspections and testing to verify the quality of both our materials and the machined products. This step is essential in maintaining the high standard that Junying is known for.

Cost and Time Efficiency: Our optimized machining processes reduce the number of setups and minimize difficulties, effectively lowering both the cost and processing time for your projects.

Variety of Finishes and Grades: LK tools offers a diverse selection of surface finishes and PEEK material grades, providing clients with multiple options to meet their specific application needs.

Choosing LK tools for your PEEK CNC machining means partnering with a provider that is committed to excellence and customer satisfaction. Our dedication to quality, precision, and efficiency ensures that your PEEK components will exceed expectations. Contact us to discuss how we can assist with your PEEK machining projects and deliver the outstanding results you require.