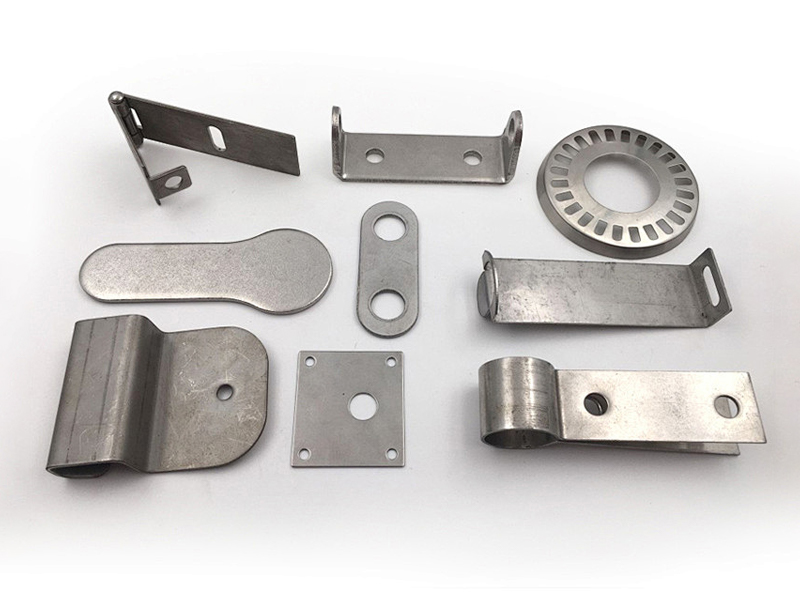

Sheet Metal Fabrication

LK tools: Your Destination for Custom Sheet Metal Fabrication

At LK tools, we specialize in custom sheet metal fabrication services, offering rapid prototyping and production capabilities that cater to a wide range of project demands. Here's an overview of what makes our services stand out:

Versatile Fabrication Techniques:

Our advanced sheet metal technology allows us to bend, punch, and cut standard gauge metals with precision, suitable for both rapid prototype development and full-scale production runs.

What Sets Us Apart:

Unlike traditional sheet metal shops, our capacity for manufacturing end-use and durable metal parts is exceptional.

We provide an extensive selection of materials and finishes to perfectly align with your project requirements.

Comprehensive Service and Tracking:

Exploring the Versatility of Sheet Metal Fabrication with Runsom Precision

Sheet metal fabrication is a comprehensive manufacturing process that transforms thin metal sheets into functional parts through various techniques such as cutting, bending, folding, punching, and assembling. Here's an insight into what sheet metal fabrication entails and how LK tools can meet your project needs:

The Process of Sheet Metal Fabrication:

Sheet metal fabrication is a subtractive process that allows for the creation of parts by altering the material through cutting and deformation.

The versatility of sheet metal means it can be manipulated into almost any shape, typically involving cutting and thermal processes.

Precision and durability are hallmarks of sheet metal parts, making them ideal for critical end-use applications like enclosures, brackets, and chassis.

From production to final shipment, LK tools offers a transparent process, allowing you to track your order every step of the way.

We pay meticulous attention to model design, user experience, and every detail throughout the production stages.

Our goal is to help product developers, designers, and manufacturers worldwide capture more market opportunities.

We strive to reduce cycle times and ensure punctual delivery, aiding in the swift market introduction of your products—whether you need a single prototype or a bulk order of 1,000 pieces.

LK tools is dedicated to providing top-tier sheet metal fabrication services that support the rapid development and production of your metal parts. Contact us to learn more about how we can assist in bringing your sheet metal projects to fruition with speed and excellence.

Choose LK tools for Your Sheet Metal Needs:

If you require custom sheet metal fabrication or are looking to outsource the manufacturing of your parts to a trustworthy supplier, Runsom Precision is your top choice in China.

By collaborating with our team, you benefit from the expertise of our engineers and machinists who can deliver rapid and cost-effective solutions for any type of part.

LK tools is committed to providing exceptional sheet metal fabrication services that meet the exacting standards of engineers and product developers. Contact us to discuss your custom fabrication needs and how we can bring your sheet metal parts to life with precision and efficiency.

The Intricate Process of Sheet Metal Fabrication Explained

Sheet metal fabrication is a multifaceted manufacturing process that transforms flat sheet metal stock into precise and durable parts. Here's a closer look at the steps involved in bringing a sheet metal design from concept to completion:

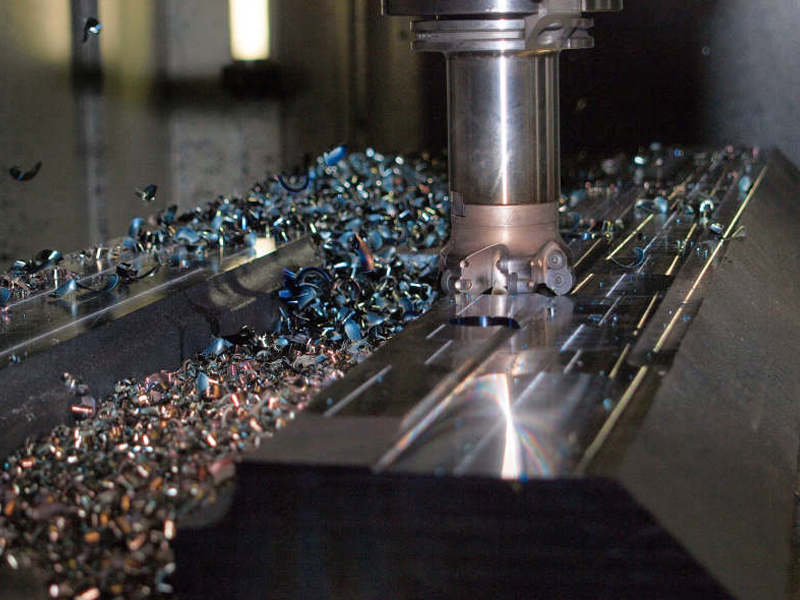

Material Removal and Cutting:

The fabrication process begins by placing thin sheet metal stock on a flat bed, where the cutting tools follow programmed patterns to shape the metal into the desired form.

Various subtractive machining processes, including punching, shearing, laser cutting, waterjet cutting, or plasma cutting, are employed to create additional features like internal holes and edge contours based on the part's design.

Material Deformation and Forming:

Once the initial cutting is complete, the sheet metal parts are moved to a press brake.

Here, they undergo forming processes such as bending to achieve their final geometries and ensure precise angles and shapes.

The Benefits of Choosing Sheet Metal Fabrication for Your Parts and Prototypes

Sheet metal fabrication stands out as a cost-effective and versatile choice for producing sheet metal parts and prototypes with consistent wall thicknesses. Here's why this process is advantageous for on-demand production:

Durability and Flexibility:

Sheet metal parts offer high durability, malleability, and pressure tolerance, making them suitable for both prototyping and end-use applications.

Cost Efficiency:

Enjoy lower prices and reduced production times due to minimal tooling and setup costs.

Economically scale your project to fit low or high production quantities without significant cost increases.

Material and Process Variety:

A wide selection of gauges is available, accommodating various laser cutting and bending requirements.

Enhanced quality of construction, coupled with low maintenance costs and frequencies, adds value to the finished product.

Assembly and Integration:

The fabricated sheet metal pieces are then assembled or fitted together with other non-sheet metal components to construct a complete product.

This stage may involve various methods, such as welding or fastening, to securely join the parts.

Surface Finishing:

In many instances, the fabricated parts undergo surface finishing operations to improve their mechanical properties, enhance their appearance, or protect against environmental factors.

Common finishing techniques include anodizing, powder coating, and painting, each contributing to the longevity and performance of the final product.

Sheet metal fabrication is a crucial process for creating components used in numerous industries, from construction and automotive to electronics and aerospace. If you're seeking precision and quality in sheet metal fabrication, our team at LK toolsis well-equipped to handle the complexities of your project and deliver parts that meet your specifications. Contact us to learn more about our sheet metal fabrication services.

Sustainability:

The sheet metal fabrication process produces minimal material waste, and the resulting parts are recyclable, contributing to more sustainable manufacturing practices.

Resistance to Elements:

Sheet metal parts are highly resistant to moisture, corrosion, and ultraviolet light, extending their service life in various environments.

High Machinability:

The inherent machinability of sheet metal allows for it to be easily transformed into nearly any shape envisioned, offering flexibility in design and application.

Sheet metal fabrication is an excellent solution for those who need robust, customizable parts quickly and cost-effectively. If you're considering sheet metal for your next project, our team can provide the expertise and quality fabrication services you require. Contact us to explore the possibilities of sheet metal fabrication for your manufacturing needs.

Optimize Manufacturing with LK tools's Sheet Metal Fabrication Services

LK tools harnesses the malleability of thin metal sheets to offer a vast array of fabrication processes, making us a leader in the industry. Here's an insight into our sheet metal capabilities:

Flexible Fabrication Techniques:

The pliability of thin sheet metal allows us to manipulate it through various processes that might not be suitable for thicker materials.

Cost-Effective Production:

Our sheet metal fabrication services are competitively priced, providing an economical solution for low-volume prototype development.

For high-volume production runs, we offer cost-saving strategies to enhance your project's budget efficiency.

Precision Services at LK tools:

Choose from a Variety of Sheet Metal Materials at LK tools

At LK tools, we offer a wide range of materials to meet the diverse needs of sheet metal fabrication projects. Each material is chosen for its specific properties and suitability for various applications. Here's a look at the common materials we use for sheet metal fabrication:

Aluminum:

A favored material due to its lightweight and corrosion resistance, with four common grades particularly well-suited for sheet metal:

3003-H14: Known for good weldability and formability.

5052-H32: Offers excellent resistance to corrosion and higher strength.

6061-T6: Balances strength, weldability, and corrosion resistance.

1100-H14: Highly ductile and workable, ideal for intricate shaping.

Stainless Steel:

Grade 304: Chosen for its excellent weldability, formability, and corrosion tolerance, making it a versatile option for a variety of sheet metal applications.

We specialize in high-precision cutting, ensuring that every part meets your exact specifications.

Our bending process allows for intricate shapes and precise angles, tailored to your design needs.

With advanced punching capabilities, we create features and holes with high accuracy.

Our skilled welding techniques join metal components seamlessly and durably.

In addition to these processes, we offer comprehensive assembly services to deliver fully constructed sheet metal parts.

LK tools is dedicated to delivering top-quality sheet metal fabrication services for projects of any size. With our expertise and state-of-the-art equipment, we're equipped to bring your designs to life with precision and efficiency. Contact us to learn more about how we can assist with your sheet metal fabrication needs.

Grade 316: Best suited for marine environments, valves, pumps, and chemical equipment due to its enhanced corrosion resistance.

Brass:

With its high formability, strength, corrosion resistance, and conductivity, brass is a perfect material for many sheet metal fabrication processes.

Other Materials:

We also work with steel and copper, each offering unique benefits for specific fabrication needs.

Custom Material Requests:

If you require a specialized material for your sheet metal project, we are here to accommodate your needs. Contact us or request an online quote now to specify your custom material requirements.

At LK tools, we are dedicated to providing high-quality sheet metal materials that align with the requirements of your project. Whether you need a durable aluminum enclosure or a precision-crafted brass component, we have the materials and expertise to deliver exceptional results.