Blow Molding Services

Understanding the Process of Blow Molding

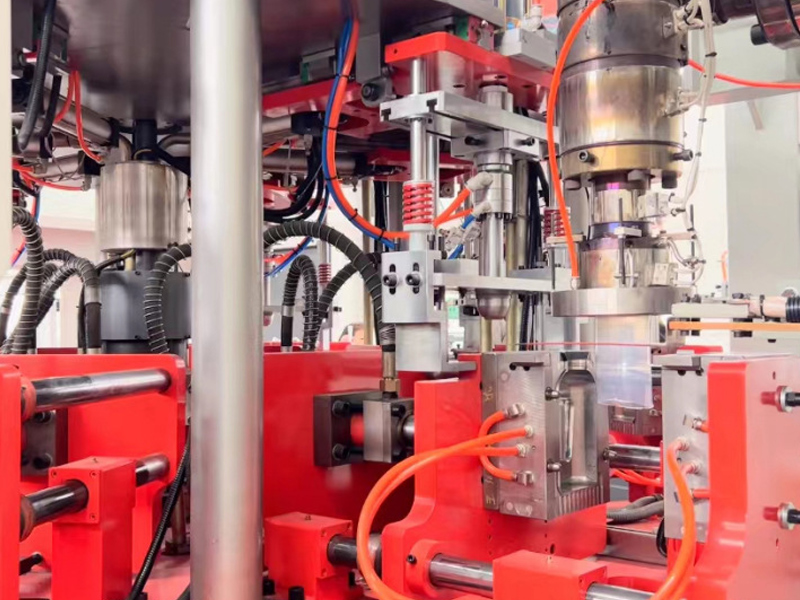

Blow molding is a manufacturing technique used to produce hollow plastic products, including everyday items such as bottles and containers. This process begins with the extrusion of a hot plastic tube, known as a parison, into a preformed open mold.

The next step involves inflating the parison with compressed air, pushing the plastic outward to conform to the mold's shape. This expansion continues until the plastic cools and solidifies, accurately capturing the intricacies of the mold cavity.

Once the plastic has set, the mold opens to reveal the finished blow molded product, which is then removed for any final post-processing steps.

Due to the intricate nature of the blow molding process, it demands the technical knowledge and creative problem-solving skills of experienced designers and engineers. Our team is equipped to handle the complexities of blow molding and is ready to answer any questions you may have. We're here to ensure a smooth, efficient production process for your hollow plastic products. Contact us to start the conversation and bring your project to fruition.

Expansive Blow Molding Capabilities and Material Expertise

Our blow molding services are distinguished by a comprehensive range of materials and product capabilities, backed by advanced mold process types. Here's a snapshot of our offerings:

Materials We Specialize In

We have extensive experience working with a variety of materials that cater to diverse industry needs:

Acrylonitrile Butadiene Styrene (ABS): Known for its toughness and impact resistance.

High Density Polyethylene (HDPE): Valued for its strength and durability.

Low Density Polyethylene (LDPE): Flexible and resistant to moisture.

Polypropylene (PP): A versatile material with a high melting point.

Polystyrene: Offers rigidity and is easy to mold.

Polyurethane: Durable with a range of hardness levels.

Santoprene: A thermoplastic rubber that combines the flexibility of rubber with the processability of plastics.

Kostrate: Impact-resistant and clear, often used for packaging.

K-Resin: Known for its clarity and gloss, suitable for medical devices and food packaging.

Product Capabilities

Our production capabilities are suited for a variety of part sizes and complexities:

Large Parts: We can handle parts up to a 5lb shot size, accommodating substantial components.

Small Parts: Our precision extends to parts as light as 5 grams, ensuring quality for even the smallest items.

Multi-component Parts: We excel in creating complex assemblies, including overmolding and insert molding, which combine different materials or components into a single part.

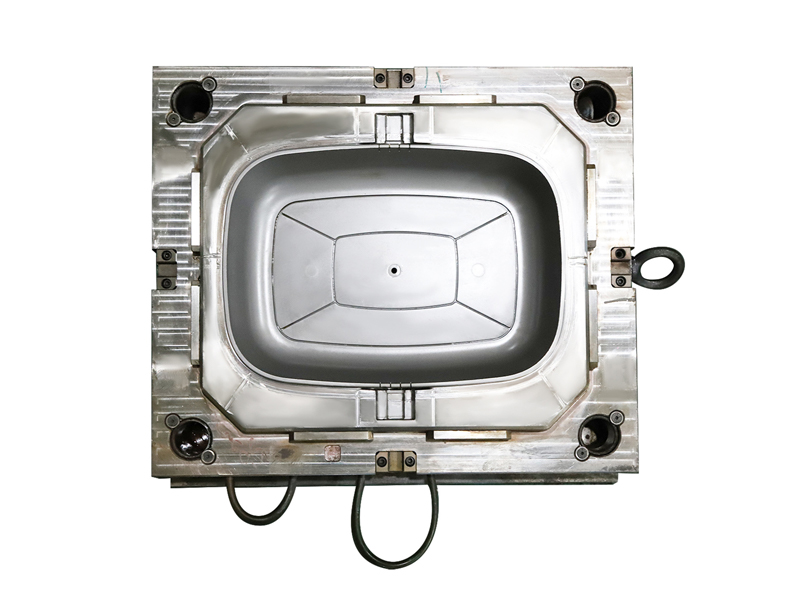

Mold Process Type

Our molds are crafted to meet the rigorous standards of the products we create:

Single Cavity Blow Mold: Typically made from 70/75 aerospace aluminum for optimal performance.

Multi Cavity Blow Mold: Incorporates beryllium pinch elements to extend the tool life, with mold longevity reaching into the millions of parts.

Air Needle and Blow Pin Blow Molds: These molds are designed for precision and consistency in the blow molding process.

Inserts or Over Molded Components: We also utilize molds that require inserts or overmolded components, catering to specialized product requirements.

Our blow molding services are designed to deliver exceptional quality and meet the specific needs of each client. Whether you require durable outdoor equipment or intricate medical devices, we have the materials, product capabilities, and mold processes to bring your vision to life. Reach out to us to discuss how our blow molding expertise can enhance your next project.

Comprehensive Capabilities and Efficient Lead Times for Custom Manufacturing

Our company is dedicated to providing an extensive range of capabilities to meet the diverse needs of our clients. From concept to completion, we offer a full suite of services to ensure your product is delivered with the highest quality.

Additional Capabilities Include:

Product Assembly: We provide comprehensive assembly services for completed products.

Custom Colors: Tailor the color of your products to match your brand or design specifications.

Engineering: Our skilled engineers are available to assist with product design and optimization.

Hot Stamping: Add decorative or informative elements to your products with our hot stamping capability. In-Mold Labeling: For both injection and blow molding, we offer in-mold labeling for a polished, durable finish.

Insert Molding/Over Molding: We specialize in creating complex parts by combining different materials into a single molded part.

Mold Making: Our in-house mold making ensures high-quality, American-made tools, with offshore options available.

Product Development: We provide inventor assistance for clients in the early stages of product creation.

Screen Printing/Pad Printing: Customize your products with detailed graphics or text.

Secondary Operations: Our services extend beyond molding to include a range of post-processing options.

Sonic Welding: Join plastic components with precision and strength using our sonic welding services.

Tooling/Mold Design: Expertise in designing molds that meet exacting specifications.

Turnkey Solutions: We handle all aspects of production, offering a complete manufacturing solution.

Warehousing/Storage: We offer storage solutions to manage inventory and ensure timely delivery.

Lead Times and Production Volume:

Lead Times: We provide quotes on a job-to-job basis, with standard production lead times of 2 weeks. New tooling typically requires 4 to 6 weeks, and expedited services are available upon request.

Production Volume: As a custom specialty company, we handle both high and low volume orders and offer small production runs with the capacity for storing large volumes to meet on-time delivery commitments.

File Formats Supported:

We work with a variety of file formats to ensure seamless integration with your design processes:

Auto Cad (DWG), Drawing Exchange Format (DXF), Graphics Interchange Format (GIF), Initial Graphics Exchange Specification (IGES), Joint Photographic Experts Group (JPG/JPEG), Portable Document Format (PDF), Pro-E or Pro/Engineer (DRW/PRT), Solid Works (SLDPRT, SLDDRW, SLDDRT), Standard for the Exchange of Product Model Data (STEP)

Our goal is to provide our clients with the tools, expertise, and services needed to bring their products to market efficiently and effectively. Contact us to discuss how we can support your manufacturing requirements with our comprehensive capabilities.

Your All-in-One Plastic Molding Solution

At LK tools, we understand the challenges clients often face with plastic molding projects, such as the need to provide their own CAD specifications or difficulties in making mold modifications. That's why we set ourselves apart by offering comprehensive, all-in-one services to make your experience seamless and stress-free.

Clients who choose Valencia Plastics receive:

Integrated Services: Unlike other facilities that may outsource aspects of the blow molding process, we handle everything from design to production in-house. This means you don't have to worry about supplying your own CAD specs or coordinating between different service providers.

Accessible Expertise: Making changes to molds should not be a daunting task. Our friendly and knowledgeable team is always on hand to assist with any modifications, ensuring that your project meets your exact specifications.

Direct Communication: We pride ourselves on clear, direct communication. You'll have access to live, English-speaking engineers who can promptly and effectively answer your questions and guide you through the process.

At Valencia Plastics, we're committed to providing an exceptional level of service and expertise. Our goal is to be your trusted partner, delivering quality and satisfaction every step of the way.

Laying the Groundwork for Success in Blow Molding with LK tools

At LK tools we believe that the key to a successful blow molding project lies in meticulous planning during the initial stages. Proper groundwork paves the way for efficient and effective production.

Here's how we ensure that your project is on the path to success:

Consultation with Experts: Engage in a detailed discussion about your project with one of our experienced engineers. A thoughtfully designed part is essential for creating a product that not only meets your expectations but is also cost-effective to manufacture.

3-D Visualization: Before we proceed to the creation of a physical mold, we'll produce a 3-D mock-up of your part. This step is crucial for accurate visualization, allowing you

to see and tweak your design, ensuring that it aligns perfectly with your vision and requirements.

Setting Realistic Expectations: Our seasoned team will offer you expert advice to set realistic expectations for your project. Their extensive experience ensures that you receive guidance that will streamline the production process, making it as smooth and efficient as possible.

With LK tools, you're not just getting a blow molding service—you're partnering with a team that's dedicated to the success of your product from the very beginning. Let us help you turn your ideas into reality with the precision and care that your project deserves.