CNC Machining Polystyrene

Precision CNC Machining of Polystyrene (PS) for Diverse Applications

Polystyrene, commonly known as PS plastic, is a versatile thermoplastic that can be machined into intricate parts for a vast array of applications. Here's what you need to know about PS plastic and its use in CNC machining:

Polystyrene is a clear, rigid material that can also be found in foam forms. It is a synthetic aromatic hydrocarbon polymer derived from the styrene monomer. Notably, PS plastic has a glass transition temperature over 100℃, making it suitable for producing disposable containers that can withstand the temperature of boiling water.

PS plastic is favored in the manufacturing industry for several reasons: it is derived from readily available raw materials, has a straightforward polymerization process, and exhibits a range of beneficial properties. These include its lightweight nature, affordability, low water absorption, dimensional stability, excellent electrical properties, high transparency, and ease of processing.

Exploring the Different Types of Polystyrene Plastic and Their Uses

Polystyrene, a versatile and widely used plastic, comes in various forms, each with distinct properties and applications. Here's an overview of the common types of polystyrene plastic:

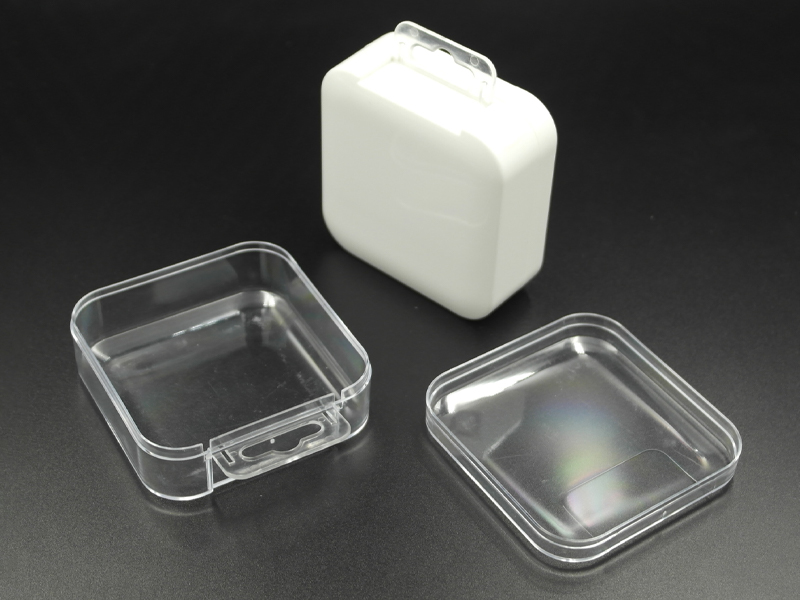

GPPS (General Purpose Polystyrene): This is a colorless, non-toxic, and odorless amorphous transparent thermoplastic. GPPS has good surface hardness, stiffness, and dimensional stability, although it is relatively brittle with low impact strength and wear resistance. It boasts excellent electrical properties, colorability, and radiation resistance but has poor resistance to sunlight. GPPS's very low water absorption makes it resistant to cold water, acids, alkalis, and other media. Typical applications include decorations, signboards, optical instrument parts, instrument shells, indicator lamp covers, transparent models in instrumentation, high-frequency capacitors in the electronics industry, automobile lamp covers, and everyday items like toothbrush handles and bottle caps.

Applications for PS plastic are extensive and diverse. It is primarily used in the production of instruments, electrical components, televisions, toys, household items, furniture, stationery, and packaging. It also serves as foam cushioning material for protective purposes.

Polystyrene materials are available in sheet, rod, and various stock shapes, making them ideal for the subtractive processes involved in CNC machining. The ability to add a wide range of colors to machined polystyrene parts further broadens their appeal and utility in different sectors.

Whether creating prototypes, small-scale models, or large-batch products, CNC machining services for PS plastic can produce parts and components with precise specifications and excellent quality. Machined polystyrene is a practical choice for businesses looking for precision parts that combine functionality with visual appeal.

HIPS (High Impact Polystyrene): HIPS is a milky white opaque amorphous polymer. It has lower tensile strength, hardness, light resistance, and stability compared to GPPS but offers significantly higher toughness and impact strength—more than seven times that of GPPS. It is also good for coloring, electrical insulation, and chemical stability. HIPS is used to manufacture various electrical and instrument parts, components for TVs, radios, tape recorders, telephones, small appliance covers, refrigerator linings, washing machine barrels, furniture, and cultural and educational supplies.

EPS (Expanded Polystyrene): EPS appears as white or colorless transparent particles that can be arbitrarily colored and exhibit good chemical resistance. They are treated with a low boiling point hydrocarbon foaming agent. Characteristics of EPS include its lightweight, low thermal conductivity, low water absorption, and good sound insulation. It also possesses certain mechanical strength and impact resistance, making it suitable for a range of applications where insulation and protection are required.

Each type of polystyrene plastic serves a unique function across various industries, from consumer goods to industrial components. Their distinct properties ensure that polystyrene remains a flexible and valuable material for a multitude of manufacturing needs.

The Advantages of Utilizing PS Plastic in Manufacturing

Polystyrene (PS) plastic is a popular choice in a wide array of manufacturing applications due to its numerous benefits. Here's why PS plastic is so advantageous:

Cost-Effective and Accessible: PS plastic is known for being inexpensive and widely available, making it an economical choice for both small-scale and mass production.

Ease of Modification: This material can be effortlessly glued, cut, and painted, offering flexibility in customization and finishing processes.

Thermoformability: PS plastic can be easily thermoformed, which means it can be heated and reshaped, allowing for the creation of complex structures and shapes.

Your Trusted Provider of Precision Polystyrene (PS) CNC Machining Services

At LK tools, we pride ourselves on delivering exceptional CNC machining services for both metal and plastic components, utilizing a wide array of materials to meet the diverse needs of our customers. Our expertise extends to the precise machining of Polystyrene (PS), a material known for its versatility and ease of fabrication.

Our talented engineers and skilled technicians are equipped to produce intricate Polystyrene structures with utmost accuracy and efficiency. Leveraging the latest in fabrication technologies, software, and state-of-the-art CNC equipment, we offer custom machining solutions for a broad range of sizes, quantities, and geometries.

Electrical Insulation: It exhibits good electrical properties, making it a suitable choice for various electronic and electrical insulation applications.

Optical Clarity: PS plastic has excellent optical properties, including clarity and light transmission, comparable to glass but with added impact resistance.

Corrosion Resistance: It offers good resistance to corrosion from chemicals and moisture, enhancing the lifespan of products made from this material.

These attributes make PS plastic a versatile and reliable option for manufacturers looking to strike a balance between cost, ease of handling, and performance. Whether for packaging, consumer products, or components in electronic devices, PS plastic offers a practical solution to meet diverse manufacturing requirements.

We possess the capability to machine or cut PS plastic through the appropriate processes, ensuring that each machined Polystyrene part conforms to your specific requirements. Our commitment to precision is reflected in our process, which relies on your digital file to minimize machining errors, thereby guaranteeing the fidelity of your design from conception to realization.

To streamline your experience, we welcome you to upload your CAD file for a fast and free online quote. Our attention to detail ensures that we keep track of every aspect of your project, allowing us to transition your design into production swiftly. Choose LK tools for your Polystyrene CNC machining needs and partner with a manufacturer who is dedicated to delivering quality parts with rapid turnaround times.

The Advantages of Partnering with LK tools for CNC Polystyrene Machining

LK tools is your ideal partner for CNC Polystyrene machining, offering a suite of benefits that cater to the precision and efficiency needs of modern manufacturing. Here's why you should choose Junying for your Polystyrene machining needs:

Advanced 5-Axis Milling: Our versatile 5-axis CNC milling machines are capable of handling a wide range of dimensions, allowing for complex machining tasks to be accomplished with ease.

Surface Finishing Options: We provide a selection of surface finishing services, including painting and coating, to enhance the appearance and performance of your Polystyrene parts.

Unmatched Precision: LK tools is committed to superior accuracy, precision, repeatability, and consistency in every project, delivering parts that meet the highest quality standards.

Efficient Production: We strive for minimized handling, fixturing time, and setup, which translates to a faster turnaround for your projects.

Direct CAD Integration: Our machining processes work directly from your CAD files or 3D drawings, ensuring a seamless transition from design to manufacture.

Reliable Communication: We maintain close and dependable communication with our clients throughout the entire production cycle, ensuring transparency and collaborative success.

With LK tools, you can expect a manufacturing partner that prioritizes your project's success, leveraging advanced technology and expertise to produce top-quality CNC Polystyrene parts. Contact us to discuss how we can meet your specific needs with our exceptional CNC machining services.