Aluminum Extrusion Services

Aluminum Extrusion: Crafting Custom Designs with Precision and Expertise

In the competitive world of manufacturing, custom design elements are essential for setting your project apart. However, the path to creating these distinctive designs can be fraught with challenges. This is where the prowess of aluminum extrusion comes into play, offering a versatile solution for bespoke design needs.

The Power of Custom Aluminum Extrusion

Aluminum extrusion is a transformative process that pushes aluminum through a die to create complex cross-sectional profiles. This technique is favored for its ability to produce strong, lightweight, and intricate shapes that are consistent along the length of the part. With aluminum extrusion, the possibilities for custom design are virtually limitless, allowing for the realization of unique and innovative elements that can elevate any project.

In-House Engineering Expertise

Our in-house engineering team at the helm of the aluminum extrusion process is a game-changer. Far from being limited to standard extrusion profiles, our engineers excel in pushing the boundaries to develop and fabricate custom shapes tailored to your exact specifications. This bespoke approach ensures that your cutting-edge designs are not only possible but executed with the highest level of precision and quality.

The Process: From Concept to Creation

The journey of custom aluminum extrusion begins with your vision. Our engineering team works closely with you to understand the

The Enduring Appeal of Aluminum for Extrusion Projects

Aluminum's allure in the realm of extrusions is undeniable, with its remarkable properties catering to a wide array of industrial and architectural applications. This material's high strength-to-weight ratio is particularly beneficial for constructing architectural features such as doors, windows, railings, and canopies, where structural integrity must be balanced with ease of handling and installation.

The Multifaceted Strengths of Aluminum Extrusions

Beyond its impressive strength-to-weight ratio, aluminum boasts a suite of attributes that make it an industry favorite:

Durability: Aluminum extrusions are known for their long-lasting nature, able to endure the elements and wear over time without significant degradation.

Low Maintenance: Unlike other materials that might require frequent upkeep, aluminum maintains its appearance and performance with minimal effort, saving time and resources.

Sustainability: As a recyclable material, aluminum supports eco-friendly practices and sustainability goals. Its recyclability does not compromise its qualities, allowing it to be reused in new applications.

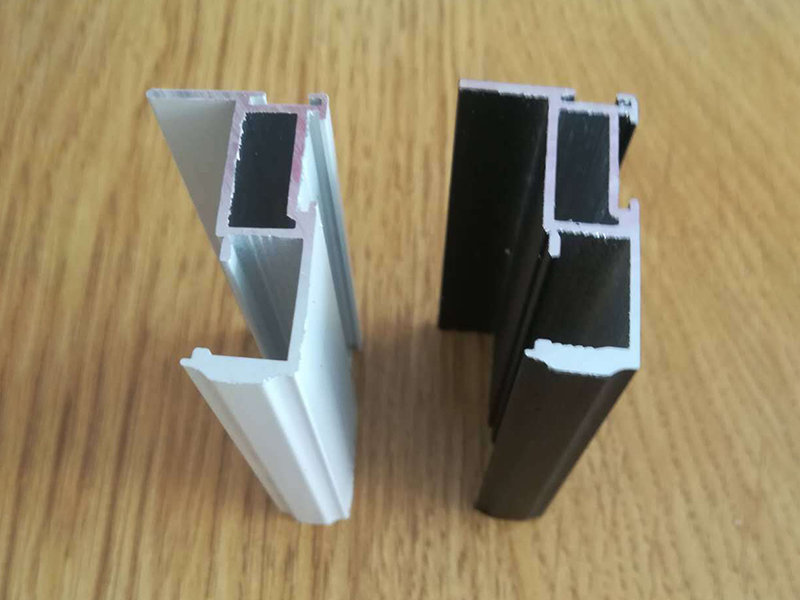

Finishing Flexibility: Aluminum's compatibility with a wide range of finishing options, including anodizing, painting, and powder coating, allows for customization to meet aesthetic preferences and functional requirements.

Advanced Conductive Properties

Aluminum's ability to conduct heat and electricity efficiently adds to its desirability. These properties make it a go-to material for components that need to dissipate heat quickly, like heat sinks in electronics, or for certain electrical applications as a lightweight alternative to copper.

Corrosion Resistance

unique requirements of your design. Using advanced CAD software, we transform your ideas into detailed extrusion die designs. Once the die is meticulously crafted, the extrusion process begins, with aluminum billets heated and then forced through the die to form your custom profile.

Versatility in Application

The versatility of aluminum extrusion makes it a perfect fit for a wide range of applications across various industries. Whether you need structural components for construction, intricate profiles for automotive parts, or custom rails for transportation systems, aluminum extrusion can be tailored to meet the demands of your project.

Advantages of Choosing Aluminum Extrusion

Strength-to-Weight Ratio: Aluminum offers an exceptional strength-to-weight ratio, making it ideal for applications where weight is a concern without sacrificing durability.

Corrosion Resistance: Aluminum naturally resists corrosion, ensuring longevity and reducing the need for additional protective coatings.

Thermal Conductivity: The metal's excellent thermal conductivity makes it suitable for heat dissipation applications, such as heat sinks and radiators.

Recyclability: Aluminum is highly recyclable, which supports sustainability initiatives and can contribute to a greener manufacturing process.

Our commitment to innovation and excellence in aluminum extrusion allows us to deliver custom solutions that are not only functional but also aesthetically pleasing. By leveraging our in-house engineering expertise, we ensure that your custom designs are brought to life with the utmost care and precision, providing you with components that truly differentiate your project. Contact us to explore how our aluminum extrusion services can transform your next design into a tangible reality.

Another advantage of aluminum is its inherent resistance to corrosion. This natural property can be further enhanced through anodizing or other treatments, ensuring that aluminum extrusions can withstand challenging environments without succumbing to rust or other corrosive damage.

A Joy to Work With

When it comes to customization, aluminum is not just practical; it's also enjoyable to work with. Its malleability during the extrusion process makes it possible to achieve intricate and specialized shapes that bring innovative solutions to life. This ease of manipulation is a boon for those designing custom parts, as it allows for creativity and precision in equal measure.

Embarking on a Custom Aluminum Extrusion Project

Working on a custom aluminum extrusion project means entering a collaborative process where your vision is meticulously brought to fruition. From the initial design phase to selecting the optimum aluminum alloy and finishing process, expect a partnership that focuses on delivering a product that meets your exact specifications. Whether for a complex component or a simple profile, aluminum extrusion offers the flexibility and quality you need for your project.

In conclusion, aluminum's combination of strength, durability, conductivity, and aesthetic versatility make it an outstanding choice for extrusions in a wide range of industries. Its user-friendly nature further cements its status as a preferred material for those seeking custom solutions. As you contemplate the path to creating a custom aluminum extrusion, be assured that aluminum's attributes will make the journey a rewarding one.

The Enduring Appeal of Aluminum for Extrusion Projects

Aluminum's allure in the realm of extrusions is undeniable, with its remarkable properties catering to a wide array of industrial and architectural applications. This material's high strength-to-weight ratio is particularly beneficial for constructing architectural features such as doors, windows, railings, and canopies, where structural integrity must be balanced with ease of handling and installation.

The Multifaceted Strengths of Aluminum Extrusions

Beyond its impressive strength-to-weight ratio, aluminum boasts a suite of attributes that make it an industry favorite:

Durability: Aluminum extrusions are known for their long-lasting nature, able to endure the elements and wear over time without significant degradation.

Low Maintenance: Unlike other materials that might require frequent upkeep, aluminum maintains its appearance and performance with minimal effort, saving time and resources.

Sustainability: As a recyclable material, aluminum supports eco-friendly practices and sustainability goals. Its recyclability does not compromise its qualities, allowing it to be reused in new applications.

Finishing Flexibility: Aluminum's compatibility with a wide range of finishing options, including anodizing, painting, and powder coating, allows for customization to meet aesthetic preferences and functional requirements.

Advanced Conductive Properties

Aluminum's ability to conduct heat and electricity efficiently adds to its desirability. These properties make it a go-to material for components that need to dissipate heat quickly, like heat sinks in electronics, or for certain electrical applications as a lightweight alternative to copper.

Corrosion Resistance

Navigating the Process of Aluminum Extrusion: A Guide to Custom Shapes and Applications

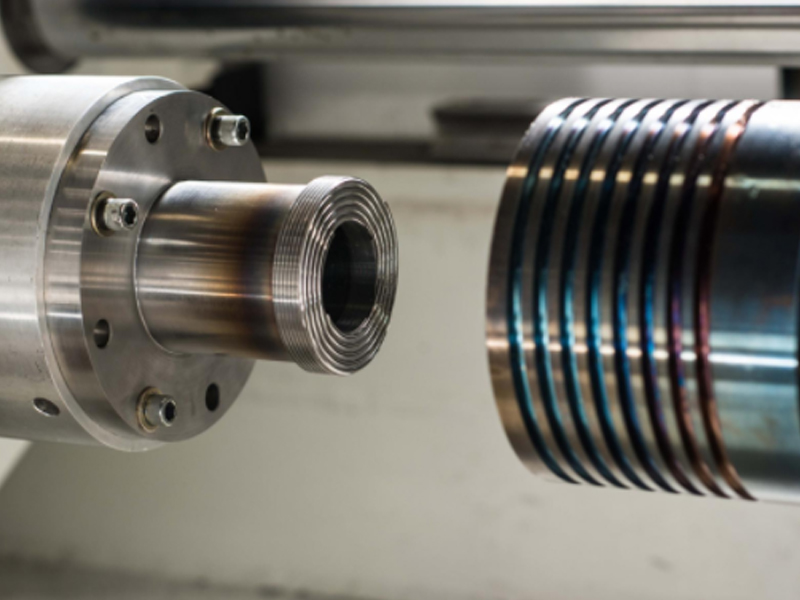

Aluminum extrusion is a fascinating and versatile manufacturing process that transforms aluminum alloy into definitive cross-sectional profiles. This process can be compared to squeezing toothpaste from a tube: as pressure is applied, the aluminum is forced through a die, taking on the shape of the die opening.

Understanding the Aluminum Extrusion Process

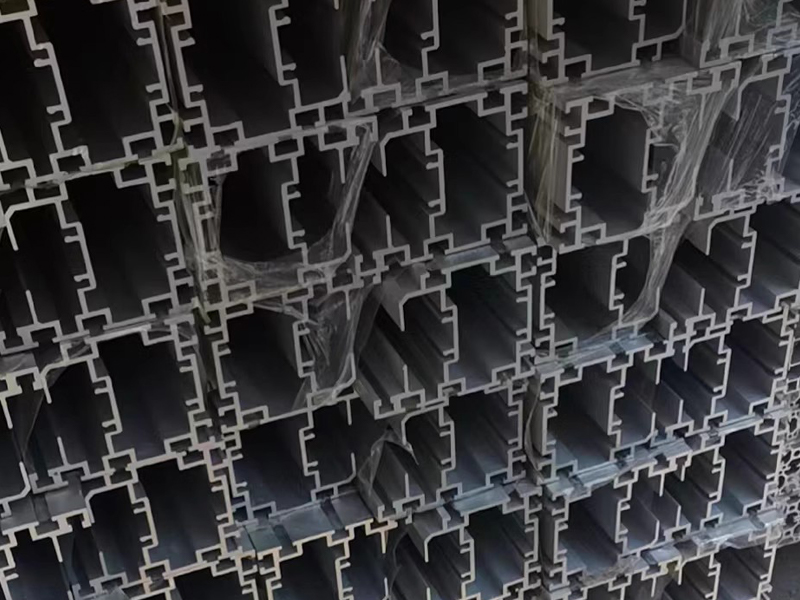

The journey of creating an extruded aluminum piece begins with the design of the extrusion die, which is essentially a robust, hollow profile that shapes the aluminum. The aluminum billet, or unshaped aluminum, is heated to a specific temperature to make it malleable and then pushed through the die using a hydraulic press or ram. The extruded aluminum emerges in the exact cross-sectional shape as the die, much like toothpaste takes the shape of the tube's nozzle.

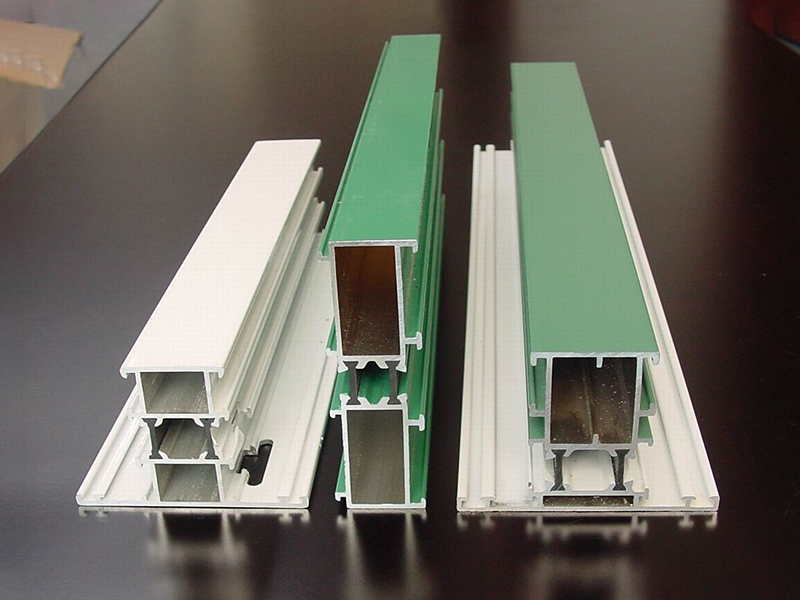

Variety of Extruded Shapes

The beauty of aluminum extrusion lies in its ability to create an almost limitless array of shapes. These shapes can include:

Solid Shapes: Without any enclosed voids, such as rods, beams, or angles, which are commonly used in construction and structural applications.

Hollow Shapes: Tubular profiles or shapes with enclosed voids, perfect for applications requiring a lightweight yet strong component.

Semi-Hollow Shapes: Profiles like "C" channels or "T" tracks that have partial voids and are often used in framing, railing systems, or other support structures.

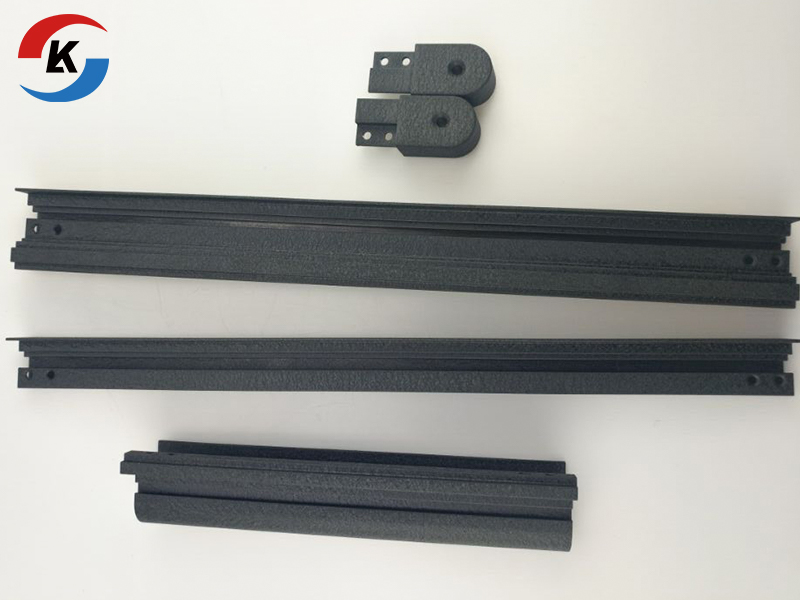

Custom aluminum extrusion allows for the production of tailored shapes that meet precise specifications for a project's structural and functional needs, as well as its aesthetic vision.

Another advantage of aluminum is its inherent resistance to corrosion. This natural property can be further enhanced through anodizing or other treatments, ensuring that aluminum extrusions can withstand challenging environments without succumbing to rust or other corrosive damage.

A Joy to Work With

When it comes to customization, aluminum is not just practical; it's also enjoyable to work with. Its malleability during the extrusion process makes it possible to achieve intricate and specialized shapes that bring innovative solutions to life. This ease of manipulation is a boon for those designing custom parts, as it allows for creativity and precision in equal measure.

Embarking on a Custom Aluminum Extrusion Project

Working on a custom aluminum extrusion project means entering a collaborative process where your vision is meticulously brought to fruition. From the initial design phase to selecting the optimum aluminum alloy and finishing process, expect a partnership that focuses on delivering a product that meets your exact specifications. Whether for a complex component or a simple profile, aluminum extrusion offers the flexibility and quality you need for your project.

In conclusion, aluminum's combination of strength, durability, conductivity, and aesthetic versatility make it an outstanding choice for extrusions in a wide range of industries. Its user-friendly nature further cements its status as a preferred material for those seeking custom solutions. As you contemplate the path to creating a custom aluminum extrusion, be assured that aluminum's attributes will make the journey a rewarding one.

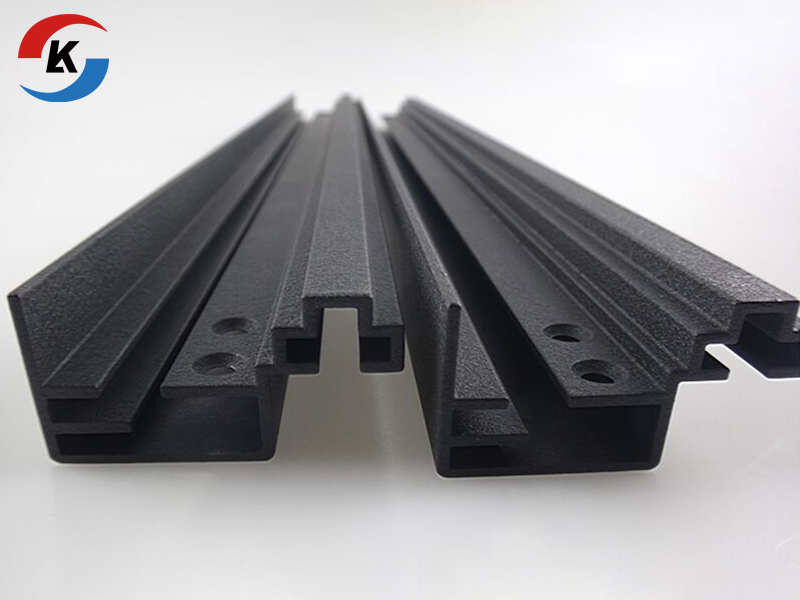

High Formability and Post-Extrusion Processing

Aluminum's high formability is one of its most celebrated traits in the extrusion process. This property makes aluminum relatively easy and cost-effective to shape, even into complex geometries that other metals might struggle to achieve without significant expense.

After the extrusion process, the aluminum profiles can undergo additional fabrication to refine their design further. This post-extrusion processing can include:

Punching: Creating holes or indentations in specific areas of the profile for assembly or functional purposes.

Drilling: Adding holes of various diameters and depths to the extruded profile for bolts, screws, or other hardware.

Machining: Shaping, threading, or detailing the aluminum extrusion to precise tolerances required for the final application.

These fabrication techniques ensure that the final dimension and functionality of your custom aluminum piece perfectly align with your project's needs.

The Versatility and Appeal of Aluminum Extrusions

Aluminum extrusions are not only popular for their structural versatility but also for their aesthetic appeal. The extrusion process, combined with aluminum's favorable properties, such as lightweight, durability, and corrosion resistance, makes it a beloved material across industries—from construction and transportation to consumer electronics and aerospace.

In summary, the ins and outs of aluminum extrusion reveal a process that is both efficient and adaptable, providing endless possibilities for custom metal shapes. Whether you need a robust beam, a lightweight tube, or a complex geometric profile, aluminum extrusion stands as a powerful solution to meet and exceed your project's requirements.