Insert Molding Services

Enhanced Assembly with Custom Plastic Insert Molding

Custom plastic insert molding is a transformative manufacturing process that seamlessly integrates plastics and metals into a cohesive assembly. This technique is efficient, reducing assembly and labor costs, while simultaneously enhancing the flexibility of design and improving the performance of the final part.

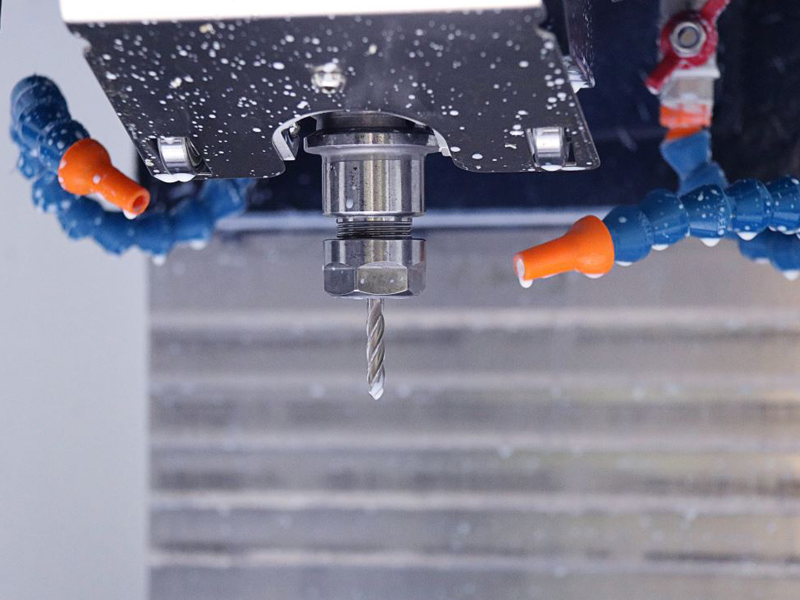

Our advanced vertical injection molding machines, featuring rotary tables, enable precise overmolding and encapsulation of metal inserts. These inserts are critical for applications requiring embedded electrical circuitry, as well as for various fastening and connecting functions. Some of the most common products that benefit from insert molding are sensors, switches, connectors, and actuators, all of which are essential components in numerous industries.

Specialized in Insert Molded Automotive Parts

In the automotive sector, insert molding is particularly advantageous, allowing for the creation of complex parts that meet rigorous industry standards. Our insert molding

The Precision of Insert Molding and Its Distinction from Overmolding

Insert molding is a sophisticated fabrication technique that involves encapsulating non-plastic inserts with thermoplastic material. The inserts vary widely and can include components such as terminals, stampings, metal rods, and assorted metal fasteners. Achieving this seamless integration requires meticulous precision molding and stringent quality controls to adhere to exacting tolerances.

Understanding Insert Injection Molding Versus Overmolding

Despite similarities in their end goals, insert molding and overmolding are distinct processes with unique applications and benefits.

Insert Molding: Integrating Strength and Durability

With insert molding, pre-manufactured metal inserts are placed into the mold cavity. The subsequent step involves molding plastic around these metal parts, resulting in a unified component. This bond is typically stronger than one

presses, which range from 55 to 300 tons, are augmented by state-of-the-art vision inspection systems. These systems meticulously check each insert for accurate placement before the press cycle continues, ensuring flawless integration and preventing any potential mold damage.

At Fabrik Molded Plastics, our insert molding capabilities are comprehensive, spanning from manual to fully automated operations. We also offer additional services, such as secondary forming and blanking. Moreover, we conduct 100% hipot and continuity testing to guarantee the integrity and functionality of every part we produce.

By choosing our custom plastic insert molding services, you are opting for a manufacturing process that merges the best properties of metal and plastic, resulting in parts that are robust, reliable, and ready for the challenges of their application. Whether you require complex automotive components or intricate electronic assemblies, we are equipped to deliver with precision and quality.

that can be achieved through post-molding assemblies. While manual loading of inserts is possible, automated loading offers enhanced efficiency and reliability by reducing the potential for human error.

Overmolding: Enhancing Function and Aesthetics

Overmolding, also known as double-shot or two-shot molding, is a process that molds plastic over an existing plastic part within the same production cycle. It merges multiple plastic types to achieve certain aesthetic or functional characteristics. The bonding can be chemical, mechanical, or a combination of both. This technique is particularly popular for adding soft-touch surfaces or grips to tools such as power drills, screwdrivers, or toothbrushes, enhancing both the product's functionality and user experience.

Both insert molding and overmolding expand the possibilities for manufacturers to create parts that are robust, functional, and aesthetically pleasing. By selecting the appropriate method based on the product requirements, manufacturers can leverage these processes to produce high-quality, multi-material components efficiently.

The Transformative Advantages of Insert Molding

Insert molding has revolutionized many industrial practices by offering an alternative to traditional metal parts. An increasing number of sectors are turning to plastic components because they are more cost-effective, resistant to corrosion, durable, and lightweight compared to many metals. Here are the key benefits that insert molding brings to the table:

Enhanced Durability

Insert molding achieves high precision and enables advanced product designs that are superior to other molding processes. Parts created with insert molding are more reliable and robust due to the integration of metal components within the plastic.

Streamlined Efficiency

Because insert molding incorporates the insert as part of the molding step, there is no need for post-molding assembly. This integration reduces the likelihood of manufacturing errors and saves significant time and labor costs, thus enhancing the overall efficiency of production operations.

Cost Savings

The insert molding process is economical, leveraging less expensive thermoplastic resins over costlier metal materials. It reduces labor expenses and lessens the need for specialized assembly equipment, contributing to overall cost-efficiency.

Lightweight Products

Diverse Applications of Insert Molding Across Sectors

Insert molding has broad applicability, proving essential in numerous industries thanks to its versatility and the added value it brings to various applications. Below are some common examples of how insert molding is utilized:

Consumer Goods

Insert molding is instrumental in producing storage solutions, personal care items, and electronics accessories. Everyday products like storage bins, toothbrushes, plastic containers, and cell phone cases are often created with this process, combining durability with design.

Automotive Components

The automotive industry benefits greatly from insert molding. Integral parts such as gears, knobs, electrical sensors, handles, and fasteners are manufactured by combining plastic and metal, resulting in components that are both sturdy and lightweight.

Medical Devices

In the medical field, where sterility is paramount, insert molding is preferred for manufacturing critical devices. Equipment like defibrillators, pacemakers, and the cables and wiring used with them are often produced via insert molding due to the ease of sterilization.

Dental Tools

Dental practitioners depend on insert-molded instruments for their ergonomic designs that facilitate easy handling, contributing to precision during dental procedures.

Defense Equipment

Plastic parts typically weigh about 50% less than their metal counterparts while still offering comparable strength. This weight reduction is particularly beneficial in industries like automotive, where lighter components can lead to improved fuel efficiency, or in the medical field, where ease of handling is crucial for surgical instruments.

Compact Size

Insert molding enables the production of smaller, thinner parts without compromising on performance or durability, offering solutions where space is at a premium or where sleek design is desired.

Wide Material Selection

This process utilizes a broad range of engineering thermoplastics, such as Nylon, PBT, PEI, and PC. Many of these materials are recyclable and known for their durability and versatility, making them suitable for a plethora of consumer and industrial applications.

Diverse Design Options

Insert molding opens up a world of design possibilities. It allows for the creation of various shapes and intricate designs, broadening the horizons for engineering and design innovation across numerous fields.

Insert molding is a strategic choice for manufacturers looking to create high-quality, integrated parts that combine the best attributes of metal and plastic. Its benefits make it a compelling option for industries aiming to enhance product performance while managing costs and embracing sustainable materials.

The defense industry utilizes insert molding for a variety of applications, including the production of binocular housings, decoys, battery packs, communication devices, and guidance systems. These components require the strength and reliability that insert molding provides.

Safety Products

Insert-molded components often feature improved grip and ergonomics, enhancing safety for users across various operations, particularly in tools and safety equipment.

Industrial Machinery

Insert molding serves industrial needs by creating parts like screws, surface mount pads, clips, spring contacts, and pins. These components often require the integration of metal for conductivity or structural integrity within a plastic housing.

Electrical and Electronics

For electrical applications, insert molding encapsulates wires in rubber or other insulating materials, making them waterproof and safer. This is crucial for products such as cell phone chargers and computer cables.

Cosmetics and Beauty Packaging

In the beauty industry, aesthetics are key. Designers leverage insert molding to develop custom packaging for makeup brushes, perfume bottles, and compacts, enhancing the visual appeal and creating eye-catching products for consumers.

Insert molding's adaptability to combine materials and create multifunctional components makes it a favored technique for industries seeking to innovate and enhance product quality. Whether for practical, safety, or aesthetic purposes, insert molding delivers solutions that meet a wide range of specialized requirements.