Injection Molding Service

Streamlined Online Injection Molding Service for Tailored Plastic Parts

Experience the convergence of technology and manufacturing with our online injection molding service, tailored for custom plastic parts. We cater to the rapid pace of innovation by offering digital manufacturing solutions for plastic prototypes and on-demand production parts with turnaround times as quick as a single day.

Whether you're looking to test a concept with a prototype or move into full-scale production, our service is designed to meet your needs efficiently and effectively. Start by requesting an injection molding quote today, and take the first step toward transforming your ideas into tangible, high-quality plastic components.

Revolutionizing Production with Advanced Injection Molding Processes

ake the seamless transition from concept prototyping to on-demand manufacturing with our state-of-the-art injection molding services. We provide an affordable pathway to high-quality, custom-molded parts, delivered within days. As a bonus, we offer your prototyping tool for free when you upgrade to an on-demand manufacturing tool.

Collaborating with a single supplier who offers free design consultation services can significantly expedite the manufacturing process. This approach enhances supply chain flexibility, ensures more consistent parts, and simplifies the qualification process, making it efficient and hassle-free.

Plastic Injection Molding

Plastic injection molding is a cornerstone manufacturing process where resin is heated until molten and then injected into a mold. This process produces final, production-grade thermoplastic parts that meet precise specifications for a multitude of applications.

Liquid Silicone Rubber Molding

Liquid silicone rubber molding is a specialized thermoset process. It combines a two-component compound that is heat cured within the mold using a platinum catalyst, resulting in flexible, durable, and high-precision silicone parts.

Overmolding & Insert Molding

Overmolding and insert molding are innovative two-part injection molding techniques. These processes involve overlaying one material onto another substrate or a metal insert, effectively creating a single, composite component. These methods are ideal for adding soft-touch surfaces to rigid parts, combining multiple colors or materials, or integrating additional functionality into a single molded unit.

Embrace the future of production with our cutting-edge injection molding processes that cater to your custom needs. Get started by requesting a quote today and take the first step towards realizing your project with speed, quality, and precision.

Broad Range of Injection Molding Materials for Every Application

Our selection of injection molding materials is extensive, encompassing over 100 different thermoplastic and thermoset options to suit a wide array of applications. If you're in search of alternatives to commonly used materials, our guide to resin substitutes offers insights into replacements for ABS, PC, PP, and other frequently molded plastics.

Thermoplastics for Versatile Applications

Our inventory of thermoplastics includes materials known for their durability, impact resistance, and versatility. Here’s a list of some of the thermoplastics we offer:

ABS: A tough, widely used plastic with good mechanical properties.

ABS/PC: A blend that combines the strength and heat resistance of polycarbonate with the flexibility of ABS.

Acetal: Known for its high stiffness, low friction, and excellent dimensional stability.

Acetal Copolymer: Similar to acetal but with improved performance in hot water environments.

Acetal Homopolymer/Delrin: Offers superior fatigue and solvent resistance.

ETPU: An elastomeric thermoplastic with high wear resistance.

HDPE: High-density polyethylene known for its high strength-to-density ratio.

LCP: Liquid crystal polymers offer high temperature performance and good chemical resistance.

LDPE: Low-density polyethylene, known for its toughness and flexibility.

LLDPE: Linear low-density polyethylene, combining strength and puncture resistance.

Nylon: Offers excellent wear resistance and low coefficient of friction.

PBT: Polybutylene terephthalate, a thermoplastic with good electrical properties.

PC/PBT: A blend that is both tough and heat resistant.

PEEK: Polyether ether ketone, known for its high temperature and chemical resistance.

PEI: Polyetherimide offers high strength and flame resistance.

PET: Polyethylene terephthalate, used in fibers for clothing and containers for liquids.

PETG: A glycol-modified version of PET, it's easier to thermoform.

PMMA (Acrylic, Plexiglas): Offers excellent transparency and weather resistance.

Polycarbonate: Known for its high impact strength and transparency.

Polypropylene: Has a good balance of thermal, chemical, and electrical properties.

PPA: Polyphthalamide, a high-heat-resistant thermoplastic.

PPE/PS: A blend of polyphenylene ether and polystyrene, offering good heat resistance.

PS: Polystyrene, ideal for rigid, low-cost, and lightweight parts.

PSU: Polysulfone, known for its toughness and stability at high temperatures.

TPU: Thermoplastic polyurethane, combining the best properties of rubber and plastic.

Thermosets for Specialized Needs

Our thermoset materials are chosen for applications that require durability and heat resistance. We offer:

Standard silicone: Available in various durometers for a range of flexibility and hardness.

Medical-grade silicone: Meets stringent standards required for medical applications.

Optical-grade silicone: Designed for optical clarity in applications like lenses and light guides.

Fluorosilicone: Offers excellent resistance to fuels and oils, ideal for automotive and aerospace applications.

Whether your project demands the strength of nylon, the clarity of PMMA, or the heat resistance of PEEK, we have the materials to bring your vision to life. Explore our options or consult with our experts to find the perfect material for your injection molding needs.

The Strategic Benefits of Injection Molding

Injection molding is a highly efficient plastic manufacturing process renowned for its capability to produce high-quality parts on a mass scale. This method is commonly employed for both low and high-volume production, and thanks to our aluminum tooling options, even prototype runs can be cost-effective.

Economical for Large-Scale Production

One of the primary advantages of injection molding is its cost-effectiveness at higher volumes. As production quantities increase, the cost per unit decreases, making this process ideal for large production runs where economies of scale come into play.

Superior Part Cosmetics and Surface Finishes

Injection molding delivers exceptional part cosmetics, providing a high-quality surface finish that is often ready-to-use without additional processing. The precision of the process allows for intricate textures, polished surfaces, and detailed features that meet strict cosmetic requirements.

Highly Repeatable for Consistent Quality

The repeatability of injection molding ensures that each part is produced with consistent quality. The automated nature of the process means that once the mold and settings are dialed in, you can expect uniform parts from the first to the last, crucial for maintaining standards across large production runs.

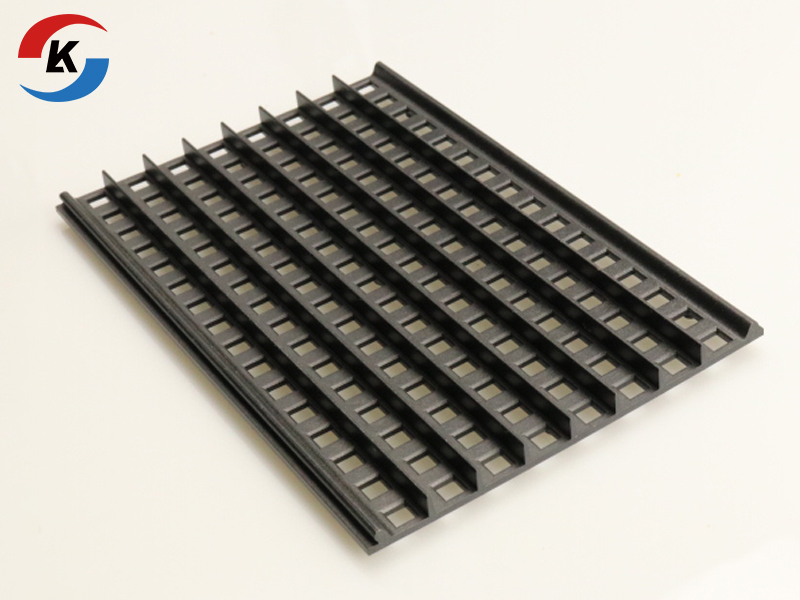

Capability to Produce Complex Parts

Injection molding excels at fabricating complex parts that other manufacturing processes might struggle to achieve. The high pressures involved in the process allow for intricate designs and fine details to be captured, making it possible to create complex geometries with precision.

Low Scrap Rates Enhance Efficiency

The efficiency of injection molding also extends to its low scrap rates. The process utilizes the material effectively, with excess plastic often being recycled and reused, minimizing waste and contributing to a more sustainable production cycle.

Diverse Material Options

Our injection molding services provide access to a large selection of thermoplastic and thermoset materials, each offering unique properties to suit various application requirements. This wide range of material options ensures that the parts produced not only perform well but also align with specific industry standards and regulations.

In summary, injection molding is a strategic choice for manufacturers seeking a reliable, cost-effective, and versatile plastic production method capable of delivering high-quality parts with precision and repeatability. Whether you are looking to launch a new product or scale up existing production, injection molding has the advantages to support your goals.

Versatile Injection Molding Applications Across Industries

Injection molding is a cornerstone in the production of plastic parts, serving a multitude of industries with its versatility and efficiency. It's particularly prevalent in the medical, consumer products, and automotive sectors, where precision and reliability are paramount. Here are some typical parts produced through injection molding:

Housings

Injection molding is ideal for creating durable, intricate housings for everything from household appliances to industrial equipment, ensuring protection and functionality.

Brackets

The process excels at producing robust brackets used in a variety of applications, providing the necessary support and structural integrity for assembly components.

Gears

Precision is key for gears, and injection molding is capable of producing high-quality, detailed gears with the exact specifications required for smooth operation in machinery and vehicles.

Single-use Medical Parts

The medical industry relies on injection molding for the production of sterile, single-use parts like surgical instruments and disposables, where safety and precision are critical.

Electrical Connectors

Injection molding is used to create electrical connectors that demand high precision and must meet specific safety standards for conductivity and insulation.

Syringes

For medical applications, injection molding produces syringes that are not only precise and reliable but also adhere to stringent health and safety regulations.

Containers

From food packaging to storage solutions, injection molding provides a method to manufacture containers of various shapes, sizes, and materials, catering to the needs of a diverse market.

The adaptability of injection molding allows for the customization of parts to meet the specific needs of an array of products and industries. With the ability to handle complex designs and a wide range of materials, injection molding continues to be a go-to process for manufacturers seeking efficient, high-quality production.