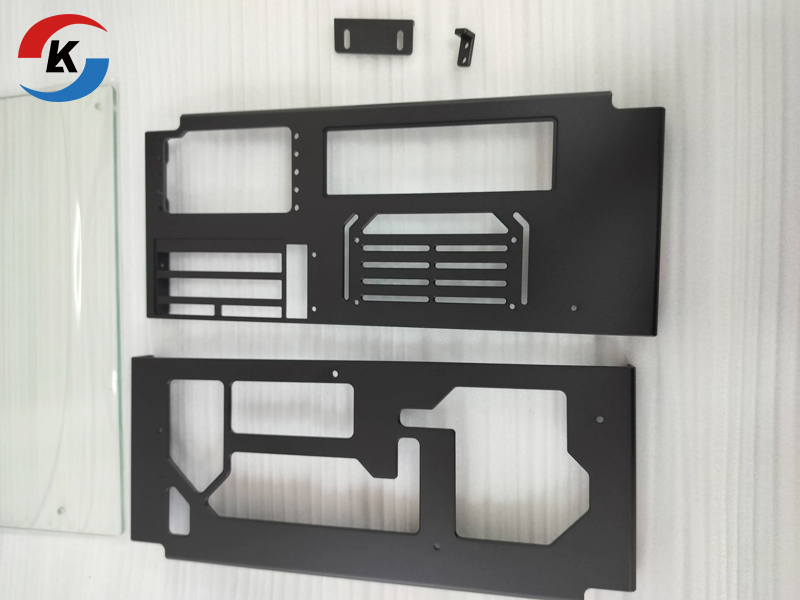

Stamping Services

High-Volume Progressive Die Metal Stamping Excellence

LK tools stands out as a distinguished metal stamping manufacturer, specializing in high-volume production runs. Our facility is equipped with state-of-the-art machinery and we possess the expertise necessary for executing precise progressive die metal stamping. This process allows for the efficient transformation of metal into complex parts through a series of stamping stations.

Our commitment to quality is evidenced by our adherence to the ISO 9001:2015 standards, an internationally recognized benchmark for quality management systems. This certification reflects our dedication to consistently delivering high-quality products and our ability to meet the stringent demands of our customers, while continuously improving our processes and outcomes.

By leveraging advanced equipment and a skilled team, we provide our clients with optimized metal stamping solutions, designed to achieve excellence in production speed, accuracy, and repeatability. Whether it's for automotive, electrical, construction, or consumer goods, LK tools is equipped to handle the rigors of high-volume metal stamping with the precision and reliability that our clients expect.

Custom Metal Stamping Services

Our custom metal stamping services are engineered to deliver the most cost-efficient solutions for high-volume manufacturing needs. By harnessing the power of high-speed presses coupled with progressive dies, we are able to produce large quantities of parts with speed, precision, and cost-effectiveness.

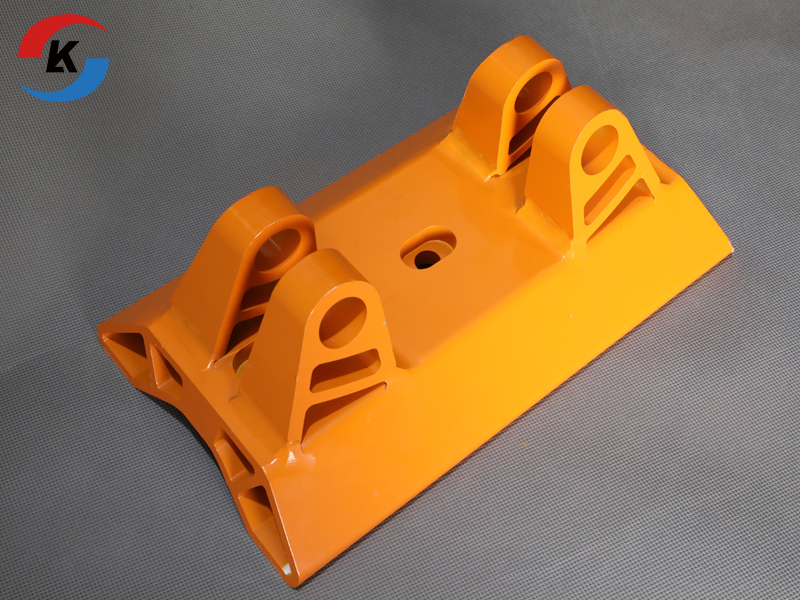

Progressive Die Stamping: The Efficient Choice

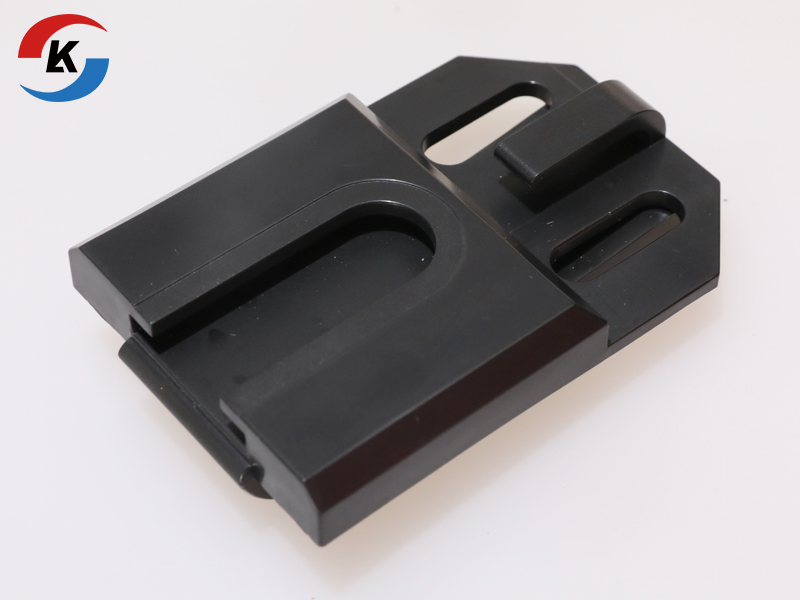

Progressive die stamping is at the heart of our operation, allowing us to create complex parts through a series of workstations, each performing a different cut, bend, or other operation. As the metal strip progresses through the press, each station builds upon the previous work until the final component is formed. This method is highly efficient for mass production, significantly reducing material waste and labor costs.

Automation for High Volume and Low Cost

When the situation calls for it, we design and construct specialized manufacturing cells that utilize

automation. This approach is tailored to high-volume, low-cost production, ensuring that we can meet the demands of our clients without compromising on quality or efficiency.

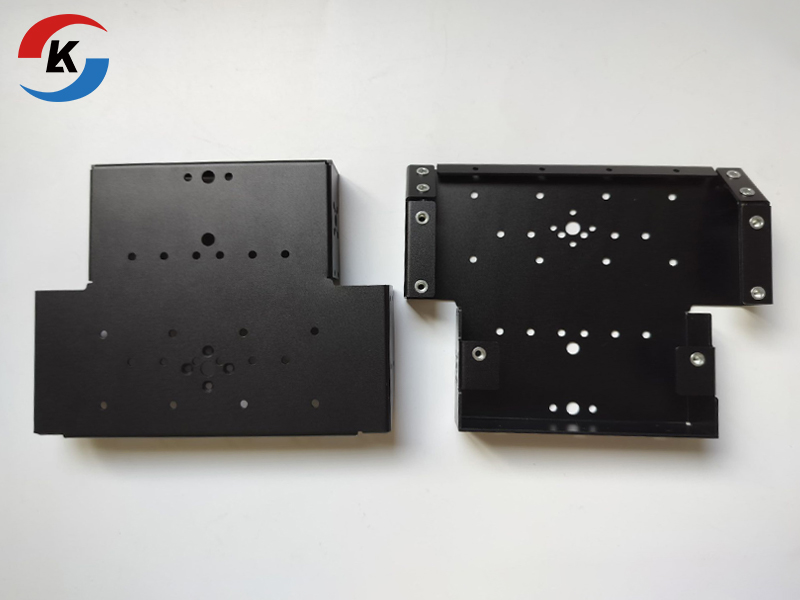

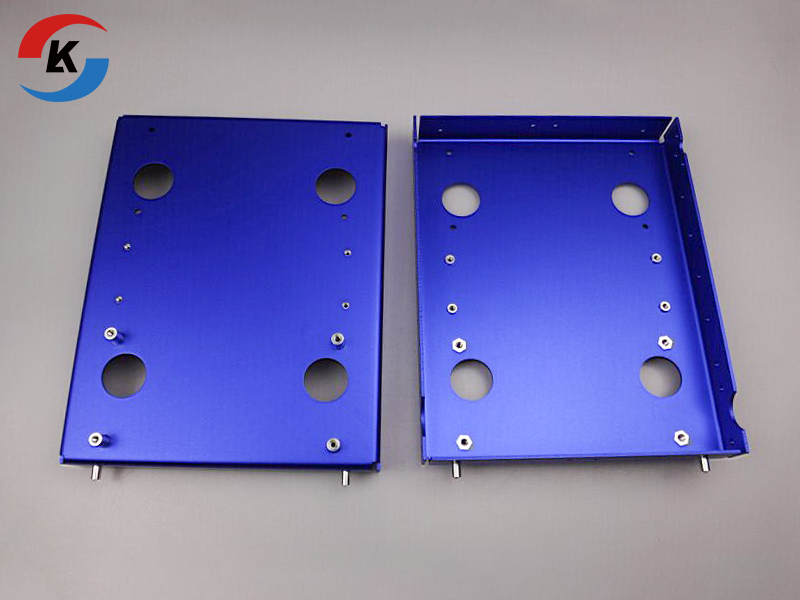

Value-Added Assembly

In addition to our stamping services, we offer value-added assembly to provide a more complete manufacturing solution. This can include various secondary operations, such as welding, fastening, and surface finishing, allowing our clients to receive fully assembled components ready for use in their applications.

Our commitment to custom metal stamping means that we work closely with our clients to deliver parts that meet their exact specifications, using materials that range from standard metals to exotic alloys. With our extensive capabilities, we are dedicated to helping our clients achieve their production goals while maintaining the highest standards of quality and efficiency.

Long-Run, High-Speed Stamping at LK tools

At LK tools, we are equipped to handle the most demanding long-run, high-speed stamping projects with a fleet of more than two dozen punch presses, capable of exerting up to 600 tons in a single stroke die closed (SSDC). With press bed sizes reaching a vast 168 inches by 54 inches and stroke ranges extending up to 12 inches, we can accommodate a wide variety of part sizes and complexities.

Our production capabilities are designed to meet high-volume needs with efficiency, as we are capable of reaching production rates of up to 50,000 parts per hour. This allows us to serve our customers with higher volume demands for progressive die stamped parts, ensuring timely delivery and consistent quality.

Our expansive 275,000 square-foot facility is structured to facilitate the most effective material handling and workflow. The layout is meticulously planned to maximize productivity and minimize waste, ensuring a smooth operation from start to finish.

We understand that transparency is important to our customers, and we welcome them to 'peek behind the curtain' to see our high-speed stamping operation in action. For those interested in learning more about our capabilities, we invite you to view our complete equipment list online. Alternatively, you can contact us directly for further information and to discuss how we can meet your stamping needs with the precision and speed that LK tools is known for.

Diverse Metal Stamping Alloys at LK tools

At LK tools, we specialize in working with a variety of metal alloys, each selected for its unique properties to meet the specific needs of our customers' projects. Here's an overview of the stamping alloys we commonly use and their applications:

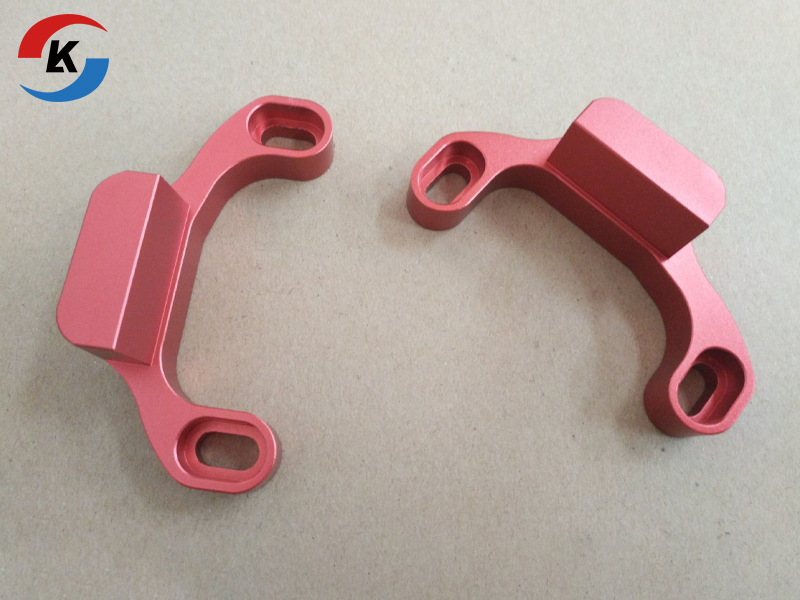

Aluminum Stampings

Aluminum is celebrated for its lightweight properties and impressive strength-to-weight ratio, making it a cost-efficient option for numerous applications. It is frequently used for building components, aircraft and aerospace parts, marine hardware, electronic chassis, and many other products where weight reduction is critical without sacrificing strength.

Stainless Steel Stampings

Renowned for its high corrosion resistance and strength, stainless steel is the go-to material for applications that demand durability and hygiene. It is widely used in industries that require food-grade materials, like the pharmaceutical sector, as well as in aerospace, transportation, and medical applications where longevity and cleanliness are paramount.

Steel Stampings

Steel's versatility shines through its malleability and ductility, making it suitable for a wide range of

applications. It is a cornerstone material for the automotive industry, various structural components, and building components, offering reliability and durability.

HSLA Stampings

High Strength Low Alloy (HSLA) steel combines high tensile strength with improved formability, weldability, and corrosion resistance compared to common low carbon steel. This alloy is a cost-effective alternative for designing parts that require high strength and the ability to carry mechanical loads, making it a smart choice for demanding engineering applications.

Copper & Red Metal Alloy Stampings

Copper and its alloys are known for their outstanding electrical and thermal conductivity, along with good corrosion resistance and machinability. As the world moves towards greater electrification, these materials become increasingly important in manufacturing components such as buss bars, switchgear, and other current-carrying parts.

At LK tools, we are adept at working with these diverse stamping alloys, leveraging their unique properties to produce high-quality, precision-stamped parts tailored to the specific needs of our clients across various industries. Whether you require the lightweight agility of aluminum or the robustness of stainless steel, we have the expertise to deliver exceptional stamped products.

The Pivotal Role of Metal Stamping in Industrial Applications

Metal stamping is a fundamental manufacturing process with a wide array of applications across various industries. Its ability to produce parts with precision and efficiency makes it indispensable for many sectors. Here are some common industrial applications of metal stamping:

Automotive Stampings

The automotive industry heavily relies on metal stamping for the production of numerous components. From engine parts to chassis and structural elements, metal stamping provides the precision and durability required for parts that must withstand rigorous use and safety standards.

Building Products

Metal stamping plays a critical role in the construction industry, producing a variety of building products. These include structural components, HVAC systems, and custom metal parts essential for both residential and commercial construction projects.

Solar BOS (Balance of System) Components

As the renewable energy sector grows, so does the need for reliable components. Metal stamping is used to create durable balance of system components for solar installations, such as mounting brackets, grounding clips, and various electrical connectors.

LED Lighting

The LED lighting industry benefits from metal stamping in the fabrication of heat sinks, housings, and reflectors. These stamped parts are essential for the efficient operation of LED lights, ensuring proper heat dissipation and light distribution.

Electric Vehicle (EV) Components

With the rise of electric vehicles, the demand for high-quality, lightweight metal parts has increased. Metal stamping is utilized to manufacture battery enclosures, motor housings, and other structural components that contribute to the overall performance and safety of EVs.

Roofing Products

Metal stamping is also used in the creation of roofing products, including metal shingles, flashing, and gutter systems. These stamped parts provide durability and weather resistance, essential qualities for long-lasting roofing solutions.

In each of these applications, metal stamping is chosen for its ability to mass-produce complex parts with tight tolerances, contributing to the advancement and efficiency of industrial manufacturing. Whether it’s for vehicles, buildings, or energy solutions, metal stamping is a key player in the production of reliable and high-quality components.

Crafting Precision: Stamping Metal from Design to Production

As a leading metal stamping manufacturer, our commitment extends beyond investing in top-notch equipment and skilled personnel. What truly distinguishes us is our engineering experience and expertise, which elevate standard stamping into a form of metalworking artistry.

Our approach is collaborative and proactive; customers often engage us at the outset of their product design phase. This early involvement is key—it allows us to offer insightful Design for Manufacturability (DFM) guidance, ensuring that the end product is not only functional and aesthetically pleasing but also optimized for efficient production.

At LK tools we pride ourselves on a quality assurance team that is data-driven and dedicated to excellence. This focus on measurable outcomes fuels our continuous improvement ethos. We stand by our world-class quality metrics and are eager to share these achievements with you, demonstrating our unwavering commitment to delivering the highest standards of precision and quality in every stamped metal product.