Custom Overmolding Services

Premium Overmolding Services for Custom Prototypes and Production Parts

If you require custom overmolded parts tailored precisely to your specifications, we are your ideal partner. IMA is committed to delivering high-quality overmolding services that cater to both prototyping and on-demand production needs.

Our expert overmolding services include:

On-Demand Molding: We provide flexible production capabilities that allow you to order the exact quantity of overmolded parts you need, exactly when you need them, without unnecessary inventory or waste.

Low-Pressure Molding: Ideal for encapsulating delicate components, our low-pressure molding services ensure that your parts are protected without damaging sensitive internal electronics or mechanisms.

Overmolding: Ideal for Specialized Production and Prototyping

Overmolding is a versatile process frequently employed for various production and prototyping needs. It is particularly suited for:

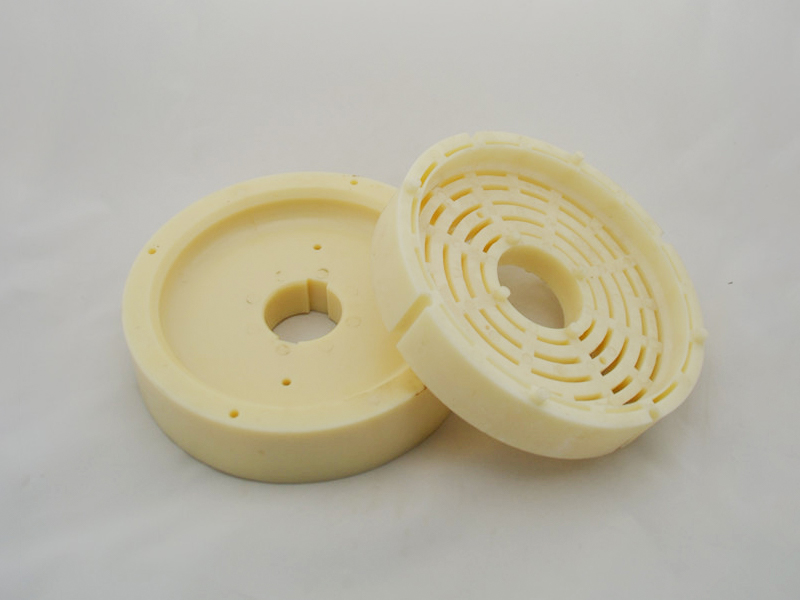

Low-Volume Production Parts: Overmolding is an excellent choice for manufacturing small quantities of parts, allowing for cost-effective production without the need for large-scale tooling investments.

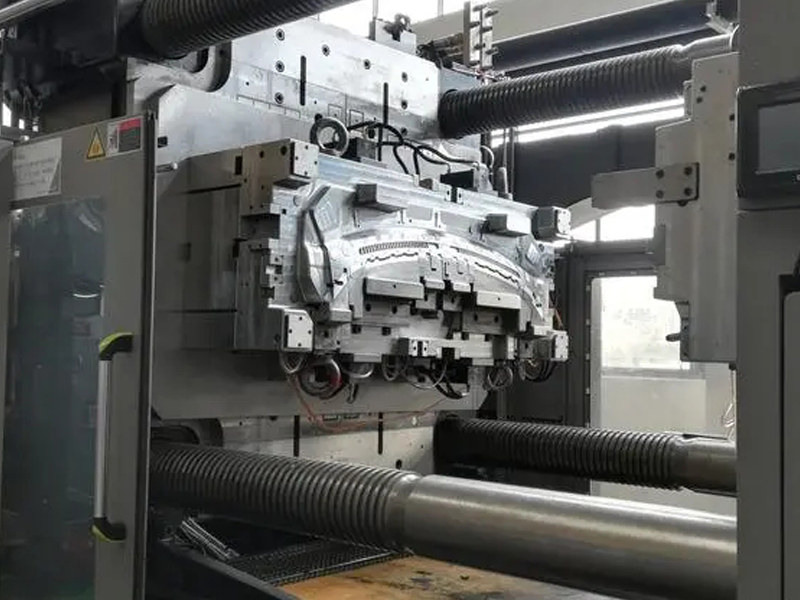

Bridge Tooling: When transitioning from prototyping to full-scale production, overmolding serves as an effective bridge tooling option, providing a smooth progression while final production tools are being created.

Pilot Runs: Before committing to mass production, overmolding is used for pilot runs to validate the manufacturing process, ensuring that parts meet design specifications and functional requirements.

Functional Prototyping and Testing: Overmolding allows engineers and designers to create functional prototypes that closely resemble the final product for testing purposes, ensuring that the part performs as intended in real-world applications.

Whether you're refining your design with a prototype or gearing up for a limited production run, overmolding offers the flexibility and precision needed to achieve high-quality results tailored to your specific project requirements.

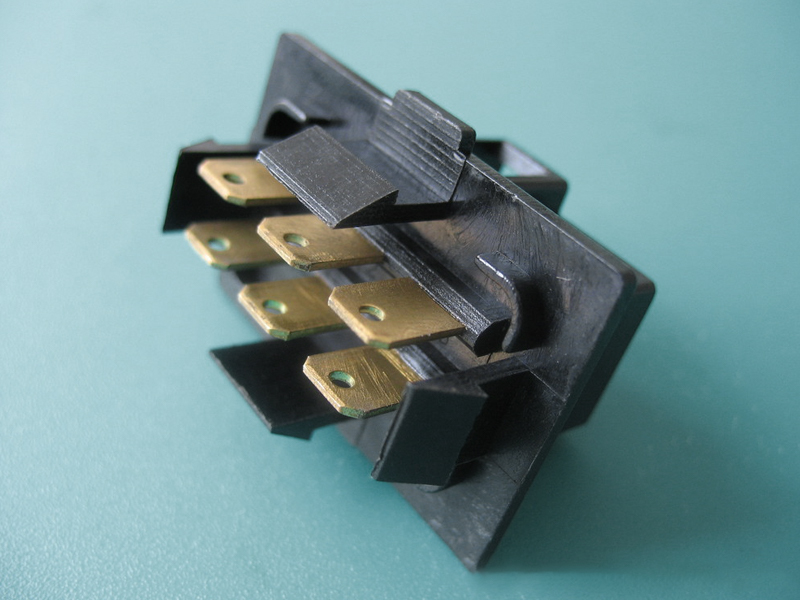

Plastic Over Plastic: We offer overmolding services that combine different types of plastics to create composite parts with varying textures, colors, or material properties in a single unit.

Plastic Over Metal: Our services extend to overmolding plastic onto metal substrates, allowing for the creation of parts that benefit from the strength of metal and the design versatility of plastic.

Additionally, we specialize in overmolded cable assemblies, which are the most cost-effective solution for sealing connectors. This process is designed to enhance the performance and reliability of your components, even in harsh environmental conditions.

When you choose IMA for your overmolding needs, you're opting for a service that is synonymous with precision, quality, and adaptability. Let us help you realize the potential of your parts with overmolding solutions that stand up to the demands of your industry.

Exploring the Efficiency and Durability of Cable Overmolding

Cable overmolding is a manufacturing process that has gained immense popularity for its ability to produce components en masse both rapidly and cost-effectively. This method is particularly advantageous for creating cable assemblies and connectors that are robust and sealed against the challenges of rugged end-use environments.

The Overmolding Process:

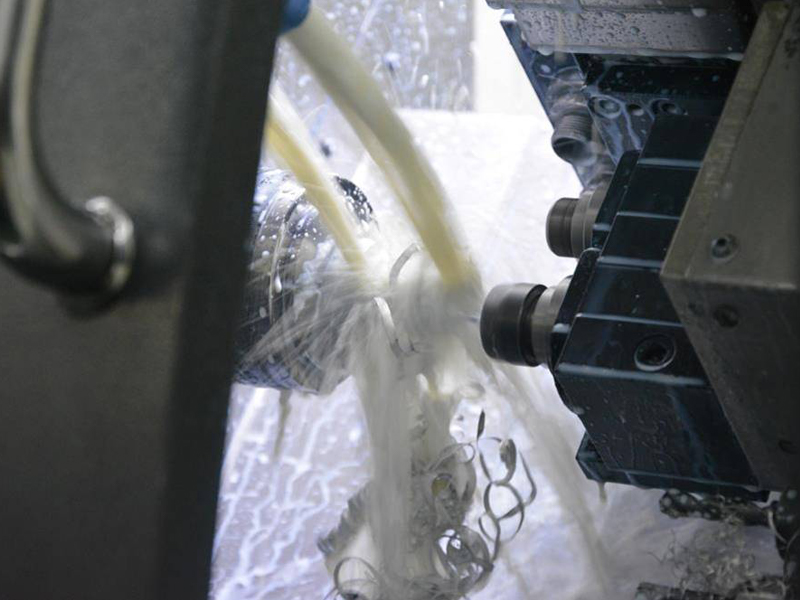

Cable overmolding typically involves a preformed part, which can be made of metal, plastic, or another material, that is placed inside a mold. Once positioned, it is overmolded with a thermoplastic resin. This encapsulates the part within the mold, resulting in a durable, single-piece component.

The overmolding technique is not only about protection; it also enhances the strength and longevity of the product. Additionally, it can provide an aesthetic benefit, allowing for a variety of colors, textures, and designs that can be tailored to specific brand or product requirements.

In essence, cable overmolding is a strategic solution for industries that require their components to withstand rigorous use while maintaining functionality and appearance. It's a process that melds practicality with design, delivering a final product that meets the highest standards of quality and resilience.

The Multifaceted Benefits of Overmolding

Overmolding offers a host of advantages that can significantly enhance both the performance and appeal of products, alongside providing cost efficiencies in production. Here are some key benefits that overmolding presents:

Enhanced Product Performance

The primary incentive for employing overmolding in product development is the notable improvement in performance it delivers. Overmolding can provide additional strength, durability, and resistance to environmental factors, which can extend the lifespan and functionality of a product.

Increased Shelf Appeal

Overmolding can utilize thermoplastic elastomers (TPE) to create surfaces that are not only comfortable to touch but also visually attractive. This aesthetic enhancement allows

Maximizing Durability and Safety with Overmolding Applications

Overmolding is a manufacturing process that has broad applications across various industries, enhancing product functionality and user safety. Here's how overmolding is applied in different sectors:

Automobile Manufacturing

In the automotive sector, overmolding is a critical process for creating parts that require the durability of metal with the versatility of plastic or rubber. Electrical sensors, gears, fasteners, and a host of other components are produced through insert molding, resulting in composite parts that contribute to the overall functionality and safety of vehicles.

Medical Industry

The medical industry demands components that can be easily and thoroughly sterilized. Overmolding is invaluable here, as it allows for the encapsulation of sensitive electrical and computer components within a sterile plastic exterior. Devices such as defibrillators and medical wiring benefit from this process,

products to stand out on the shelves, catching the eye of potential customers and distinguishing them from competitors.

Reduced Production Costs

One of the unique aspects of overmolding is its ability to add value in several dimensions while simultaneously reducing production costs. By integrating multiple components or materials into a single process, overmolding reduces the need for multiple manufacturing steps, streamlining production, and saving on labor and assembly costs.

Overall, overmolding is a strategic manufacturing technique that can significantly elevate a product's marketability and performance while optimizing production efficiency and reducing costs—a win-win for manufacturers and consumers alike.

protecting the delicate internal parts while ensuring that the exterior can withstand rigorous cleaning protocols.

Electrical Engineering

Overmolding rubber onto electrical cables is a common practice for enhancing safety and providing water resistance. This process is widely used in consumer electronics, where it ensures that products like smartphones and computer chargers are safe to handle. The technique can also be used to bundle multiple wires into a single rubber sheath or to color-code individual wires, aiding both in insulation and in easy identification.

The applications of overmolding are diverse, reflecting its ability to marry the strength of one material with the protective qualities of another. Whether it's creating a rugged part for a car, a sterilizable medical device, or a safe electrical component, overmolding is a key process that improves product performance, user safety, and overall longevity.