CNC Machining PMMA

The Advantages of CNC Machining in Acrylic PMMA Plastic

PMMA plastic, widely recognized for its exceptional qualities, is a preferred material in CNC machining operations, including turning and milling. Its transparency and rigidity make it an excellent glass substitute, offering a combination of visual clarity and durability that is hard to match.

Poly(methyl methacrylate), commonly known as Acrylic, Perspex, or Plexiglass, is an engineering plastic that is commonly found in transparent sheet form. It serves as a lightweight and shatter-resistant alternative to glass, and is often chosen over polycarbonate when the requirements for tensile strength, flexural strength, transparency, polishability, and UV tolerance outweigh the need for superior impact strength, chemical resistance, and heat resistance.

The Distinct Advantages of PMMA/Acrylic Plastic in Manufacturing

PMMA, also known as Acrylic plastic, offers a host of benefits that make it an appealing choice for a range of manufacturing applications. Here are the key advantages of using PMMA/Acrylic plastic:

Exceptional Transparency: Acrylic boasts crystal-clear transparency, making it an excellent alternative to glass for a variety of visual applications.

Optical and Insulating Properties: It offers excellent optical clarity alongside good insulation, making it suitable for applications in optics and electrical insulation.

Resistance to Abrasion and Weathering: PMMA is resistant to the elements, sustaining its properties over time, which is vital for outdoor applications.

Ease of Machining: Acrylic can be easily machined, allowing for a smooth manufacturing process and the creation of complex shapes and fine details.

Superior Aging Resistance: It resists the effects of aging exceptionally well, maintaining its appearance and properties even after prolonged use.

Strength and Durability: Acrylic exhibits strong toughness, commendable tensile strength, and flexural strength, enabling it to withstand physical stresses.

PMMA plastic's ease of processing makes it a popular choice for creating a variety of visual displays, including signs, lightboxes, and billboards, through Acrylic CNC machining techniques. Additionally, machined PMMA parts are utilized in the construction and chemical industries due to their robustness and adaptability.

The performance characteristics of PMMA, such as hardness, weather resistance, and high-temperature resistance, are indicative of the quality of the raw material used. These properties are critical as they directly influence whether the material will experience shrinkage, bending, deformation, or surface cracking during processing.

CNC machining in PMMA plastic harnesses these inherent advantages, enabling the production of precise and aesthetically pleasing parts that are suited for a wide range of applications. Whether for architectural projects or industrial applications, the versatility and performance of CNC machined PMMA parts make them an invaluable resource in today's market.

Chemical Stability and Mechanical Properties: The material's chemical stability and mechanical properties make it reliable for a variety of industrial uses.

Dimensional Stability: PMMA maintains its shape and size, an important characteristic for precision components.

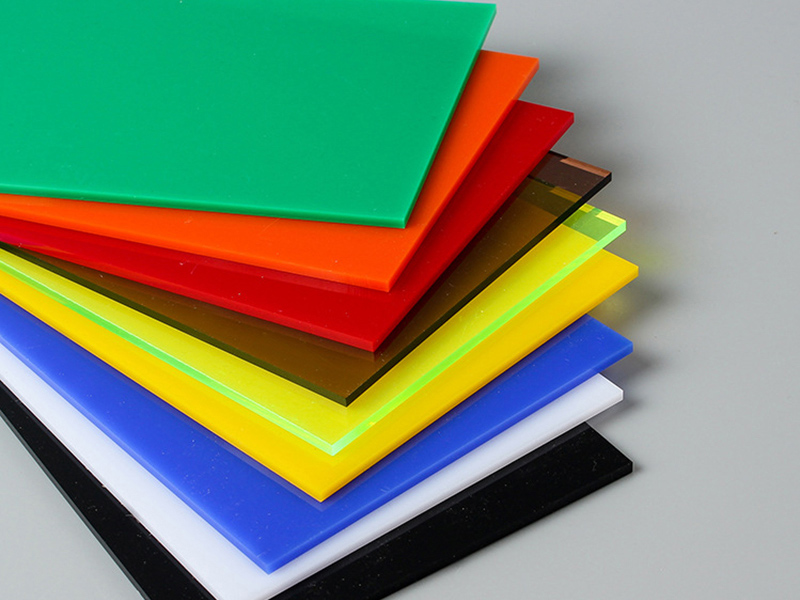

Variety of Forms and Colors: It is available in a wide range of forms and colors, offering flexibility in design and aesthetic options.

Economic Efficiency: Acrylic provides these numerous benefits at a low cost, making it a cost-effective material choice.

Eco-friendly: Its recyclability and biocompatibility make PMMA an environmentally friendly option that aligns with sustainability goals.

The combination of these attributes ensures that PMMA/Acrylic plastic is a highly valuable material in industries such as construction, automotive, consumer products, and medical devices. Its versatility, along with its economical and eco-friendly nature, positions it as a go-to material for manufacturers looking to produce high-quality parts and products.

Precision Acrylic CNC Machining Services for Custom PMMA Parts

Acrylic, also known as PMMA (Poly methyl methacrylate), is a versatile material that lends itself well to various fabrication techniques, including CNC machining, 3D printing, and injection molding. At LK tools, our Acrylic CNC machining services offer distinct advantages, enabling us to produce parts with high accuracy and cost efficiency.

Whether you require precision CNC machined PMMA parts or prototypes, LK tools provides a reliable and safe manufacturing solution. Our CNC machined Acrylic parts are not only versatile but also durable, ensuring longevity and performance. However, it is important to note that PMMA is somewhat fragile and can be prone to failure under tensile and compressive forces.

The Diverse Utility of Acrylic CNC Machined Parts Across Industries

Acrylic, known for its versatility and aesthetic appeal, is increasingly becoming a material of choice for CNC machined parts across a variety of industries. Here is an overview of some common applications where Acrylic CNC machining parts are utilized:

Sanitary Ware: Acrylic is now considered the best new material for sanitary ware following ceramics. It offers a high brightness finish that traditional ceramic materials cannot match, along with the benefits of toughness and resistance to damage. Acrylic's vibrant colors cater to a wide range of personal tastes, leading to its use in creating stylish and durable basins, bathtubs, and toilets that also support environmental conservation efforts.

Architecture: In the field of construction, Acrylic is used to produce windows, soundproof doors, telephone booths, and other architectural elements that benefit from its clarity and sound insulating properties.

Advertising: The material's translucency makes it perfect for lightboxes, signboards, and exhibition racks, where it can capture and diffuse light to draw attention effectively.

Transportation: Acrylic finds application in the transportation industry as well, being used in doors and windows of trains, cars, and other vehicles due to its lightweight nature and shatter resistance.

Medical: The safety and clarity of Acrylic are crucial in the medical field, where it is used to manufacture baby incubators and various surgical medical instruments.

Industrial: Its ease of machining and durability make it suitable for industrial applications, such as instrument panels and covers.

Lighting: In the lighting industry, Acrylic is used to produce components such as fluorescent lamp shades, chandeliers, and street lamp covers, thanks to its ability to diffuse light and withstand varying environmental conditions.

Acrylic CNC machining parts are highly valued for their light weight, affordability, and machinability, making them a practical alternative to glass and other heavier or more costly materials. Whether for aesthetic, functional, or safety purposes, Acrylic CNC machined parts continue to expand their presence in numerous sectors, offering designers and engineers a reliable material that complements modern manufacturing demands.

Leveraging years of experience, LK tools has honed the ability to carry out meticulous machining operations that minimize the risk of failure during the manufacturing process. This careful approach reduces material waste and enhances overall efficiency. With CNC machining, we significantly increase the speed of Acrylic fabrication while ensuring precision and accuracy.

Our team of skilled engineers and designers is equipped to tailor solutions to meet your specific requirements. LK tools also offers a range of surface finishing options, including painting and polishing, to meet any aesthetic needs you may have for your Acrylic parts.

Choose LK tools for your PMMA/Acrylic CNC machining needs and benefit from our commitment to quality, efficiency, and customer satisfaction. Contact us to discuss how we can bring your Acrylic part designs to fruition with the utmost precision and care.

The Advantages of Opting for LK tools's Precision CNC Acrylic Machining Services

When it comes to CNC acrylic machining, LK tools stands as a top choice for customers seeking a blend of aesthetic excellence and functional precision. Here's why LK tools is the go-to manufacturer for your CNC acrylic needs:

Superior Aesthetic Finish: Our range of surface finishing services ensures that the aesthetic and cosmetic effects of your acrylic parts meet the highest standards, enhancing their appearance and functionality.

Color Variety Without Compromising Clarity: We offer a wide selection of colors for your acrylic parts, allowing for customization while maintaining the material's inherent transparency.

Capability for Complex Designs: Our advanced CNC machining capabilities allow for the creation of complex shapes and intricate designs, providing flexibility to bring even the most challenging projects to life.

Lightweight and Durable Parts: LK tools's expertise in machining PMMA (Polymethyl methacrylate) results in parts that are not only light and strong but also economical, offering a cost-effective alternative to heavier or more expensive materials.

High-Quality Prototyping: We specialize in producing premium quality prototypes in the most cost and time-efficient manner, ensuring a quick turnaround without sacrificing detail or quality.

By choosing LK tools for your CNC acrylic machining needs, you're partnering with a manufacturer that understands the importance of marrying visual appeal with material performance. Our commitment to delivering top-tier machined PMMA parts, combined with our attention to detail and customer service, makes us a trusted leader in the industry. Reach out to us to discover how we can elevate your project with our expert CNC acrylic machining services.