CNC Milling Parts Service

Expert CNC Milling Services for Custom Acrylic Epoxy Phone Holders

our company, we specialize in CNC milling services that bring your custom designs to life, including the creation of sophisticated acrylic epoxy phone holders. Here's an insight into the components and production process:

Components of an Acrylic Epoxy Phone Holder:

Acrylic Pedestal: The base of the phone holder, molded to precise dimensions for stability.

PET (Polyethylene Terephthalate): A durable and versatile plastic used for high-quality printing.

Double-Sided Adhesive: Ensures a secure bond between the PET and the acrylic pedestal.

Eco-Friendly Ink: Utilized for vibrant and sustainable pattern printing on PET.

Epoxy Resin: Provides a clear, protective coating for the PET layer.

Metal Ring: Adds functionality to the phone holder for easier handling or display.

Production Process Overview:

Step 1: The acrylic pedestal is formed using a precision mold.

Step 2: Patterns are printed onto the PET layer using eco-friendly inks.

Step 3: Double-sided adhesive is applied to PET, which is then die-cut to the pedestal's shape.

CNC Milling Design Guidelines and Capabilities by LK tools

At LK tools, we provide comprehensive guidelines for CNC milling to ensure optimal part manufacturability, aesthetic quality, and efficient production. For an in-depth look at all our design guidelines, we invite you to visit our dedicated page. Below are some key considerations and capabilities:

Maximum Milling Dimensions:

The maximum milling depth available is 2 in. (50.8mm) from either side of the part.

For material-specific milling dimensions, refer to our detailed charts on maximum part extents.

Material-Specific Maximum Dimensions (US and Metric):

3-axis Hard Metals (Titanium, Stainless Steels, Alloy Steel)*: Up to 10 in. x 7 in. x 1.75 in. (254mm x 178mm x 44.5mm).

3-axis Brass and Copper: Up to 10 in. x 7 in. x 2.75 in. (254mm x 178mm x 69.9mm).

3-axis Aluminum and Plastic: Up to 10 in. x 7 in. x 3.75 in. (254mm x 178mm x 95.3mm).

3-axis ABS, Acetal (Two-sided machining only): Up to 10 in. x 14 in. x 1.75 in. (254mm x 356mm x 44.5mm).

Step 4: The die-cut PET is affixed to the pedestal, with options to add decorative elements.

Step 5: Transparent epoxy resin is applied to the PET for a smooth finish.

Step 6: The pedestal is baked, solidifying the resin for a durable finish.

Step 7: The metal ring is assembled to the holder.

Step 8: Double-sided adhesive is placed on the holder's back for mounting.

Upon completing these steps, the materials are fused into a single, enduring unit. The epoxy process ensures a strong bond, akin to the creation of amber.

CNC Milling Service:

Our service delivers custom milled parts swiftly, suitable for both rapid prototyping and production.

Certifications: We are ISO 9001:2015, AS9100D, and ITAR registered, adhering to rigorous quality standards.

Capabilities: Our facility offers 3-axis and 5-axis indexed milling for manufacturing from over 30 engineering-grade materials.

Additional Services: Benefit from competitive pricing at higher quantities, FAI reporting, material certifications, and finishing options like anodizing and chromate plating.

Our CNC milling is ideal for various applications, including functional prototypes, jigs and fixtures, and low-volume production components. To learn more about our capabilities, materials, surface finishes, or take a virtual tour of our machine shop, jump to the relevant section on our website or contact us directly. Let us help you bring precision and innovation to your next project.

3-axis ABS, Acetal, Nylon (Two-sided machining only): Up to 22 in. x 14 in. x 0.75 in. (559mm x 356mm x 19.1mm).

3-axis Aluminum (Two-sided machining only): Up to 22 in. x 14 in. x 3.75 in. (559mm x 356mm x 95.3mm).

5-axis Aluminum, Brass, Copper, Hard metals*: Up to 2.6 in. x 2.9 in. x 3.9 in. (66mm x 73mm x 99mm).

*Hard metals include grades like Titanium (6Al-4V), Stainless Steels (303, 304, 316, 17-4PH), and Alloy Steel (4140).

Minimum Dimensions, Threading, Tolerances, Radii, and Text:

Our CNC milling services offer precise threading options, tight tolerances, and detailed text engraving. Minimum dimensions are established to ensure machinability, while radii and text specifications are determined by the CNC milling process and material properties.

LK tools's CNC milling capabilities are designed to accommodate a wide range of industries and applications, ensuring that your machined parts are produced with the highest precision and quality. Whether your project involves complex geometries or requires stringent tolerances, our team is equipped to deliver results that exceed expectations. Contact us today to discuss your CNC milling needs and explore the full extent of our capabilities.

Our Broad Selection of CNC Milling Materials for Every Application

At our facility, we have curated an extensive inventory of more than 30 production-grade plastic and metal materials to meet the diverse needs of various industries and part applications. Here's a snapshot of the materials we offer for CNC milling:

CNC Milled Plastics:

ABS: Known for its toughness and impact resistance.

Acetal: Offers high strength and stiffness with good moisture resistance.

CPVC: Can withstand higher temperatures than standard PVC.

HDPE: Recognized for its high strength-to-density ratio.

LDPE: Noted for its flexibility and low-temperature impact resistance.

Nylon: Durable with high wear resistance.

PEEK: Exceptional mechanical and chemical resistance properties.

PEI: High strength and heat resistance.

PET: Good for food-grade applications.

PMMA (Acrylic): Excellent clarity and UV resistance.

Polycarbonate: Very high impact strength.

Polypropylene: Good chemical resistance and toughness.

POM (Delrin): High stiffness and dimensional stability.

PPSU: Superior toughness and thermal stability.

Adhering to Anodizing and Chromate Plating Standards for Superior Finishes

Our metal finishing capabilities include a comprehensive range of anodizing and chromate plating services that adhere to strict military specifications. Here's an overview of our anodizing and chromate plating specifications, along with our quick-turn finishing options:

Anodizing Specifications:

MIL-A-8625 Type II, Class 2 (Black): Standard anodize for added corrosion resistance and surface hardness.

MIL-A-8625 Type II, Class 1 (Clear): Standard anodize that maintains the natural color of aluminum while providing protective benefits.

MIL-A-8625 Type III, Class 2 (Black): Hard anodize that gives aluminum parts a thicker, harder surface layer for extreme wear resistance.

Chromate Plating Specification:

MIL-DTL-5541 Type II, Class 3 (Clear): Chromate plating that offers corrosion protection while maintaining electrical conductivity.

PS (Polystyrene): Easy to machine and rigid.

PSU: High strength and heat resistance.

PTFE: Outstanding chemical resistance and low friction.

PVC: Good electrical insulation properties and chemical resistance.

CNC Milled Metals:

Aluminum: Lightweight with good strength and corrosion resistance.

Brass: Good machinability and aesthetic appeal.

Copper: High electrical and thermal conductivity.

Stainless Steel: Excellent corrosion resistance and strength.

Steel Alloy: Diverse alloys offering various strengths and properties.

Steel Mild Low Carbon: Great for welding and forming.

Titanium: High strength-to-weight ratio and corrosion resistance.

Our selection of CNC milling materials ensures that, whether you're creating a prototype or a production part, you have access to the right material for your specific requirements. With a variety of plastics for lightweight and corrosion-resistant applications, and metals for strength and durability, we have the material solutions for your CNC milling needs. Contact us to learn more about how our materials can contribute to the success of your project.

Quick-Turn Finishing:

To receive parts with finishing in as fast as 4 days, please adhere to the following requirements:

Material eligibility includes Aluminum 6061/6082 and 7075.

Threaded holes must be plugged.

No masking options are available for quick-turn finishing.

High-Requirement Finishing:

For projects with AS9100 and ITAR requirements or more complex finishing needs, consider our domestic precision machining services. If your components require specialized colors or materials, like titanium or nickel, our digital network of manufacturers is equipped to handle these advanced anodizing and plating requirements.

Whether you need standard anodized finishes or specialized plating services, we are committed to delivering high-quality results that meet your project's specifications. Contact us to discuss your anodizing and chromate plating needs and take advantage of our expert finishing services.

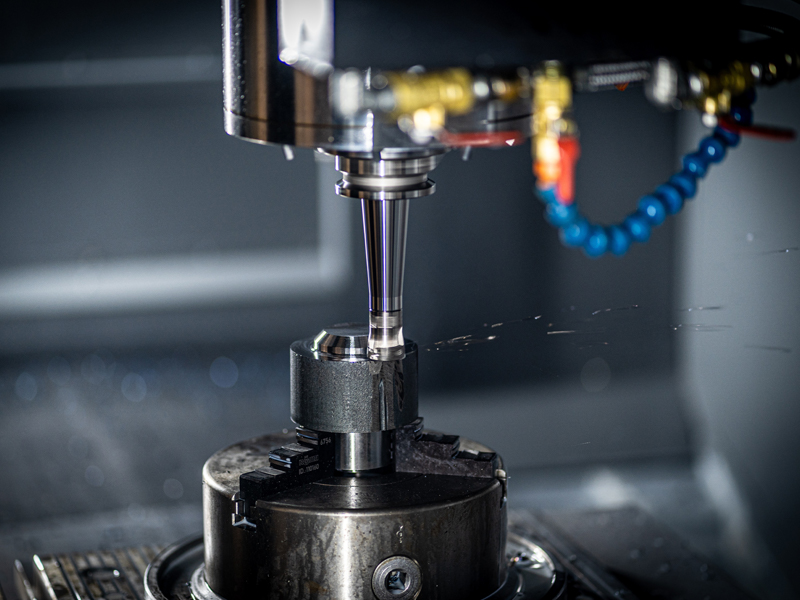

Understanding CNC Milling: The Subtractive Manufacturing Process

CNC milling is a fundamental subtractive manufacturing technique that shapes raw material into finished parts. Here's an overview of how the CNC milling process unfolds:

Material Fixturing: The process begins by securing a block of metal or plastic material inside the CNC milling machine.

Programming and Milling: Using G-code, the CNC machine is programmed to rapidly and precisely mill the part out of the raw material block. The code directs the milling tools on their paths and dictates the exact movements needed to produce the part.

Advanced CNC Machines: Our sophisticated 3- and 5-axis CNC machines are outfitted with diverse toolsets that enhance both efficiency and production speed, allowing for complex geometries and precise detailing.

As-Milled Finish for Plastics: Machined plastic parts typically retain the as-milled finish, which means tool marks from the milling process may be visible on the surface of the part.

Finishing Options for Metals: For metal parts, there are additional finishing choices available, such as anodizing and chromate plating, to enhance the appearance and durability of the parts.

Final Steps and Shipping: Once the milling run is complete and the desired surface finish is applied, the parts are packaged and shipped promptly to their destination.

CNC milling transforms a simple block of material into intricate parts that meet your design specifications. Whether your project requires basic as-milled finishes or more sophisticated post-processing, our CNC milling services are designed to deliver precision parts with a swift turnaround. Contact us to learn more about our capabilities and start your next project with the power of CNC milling.