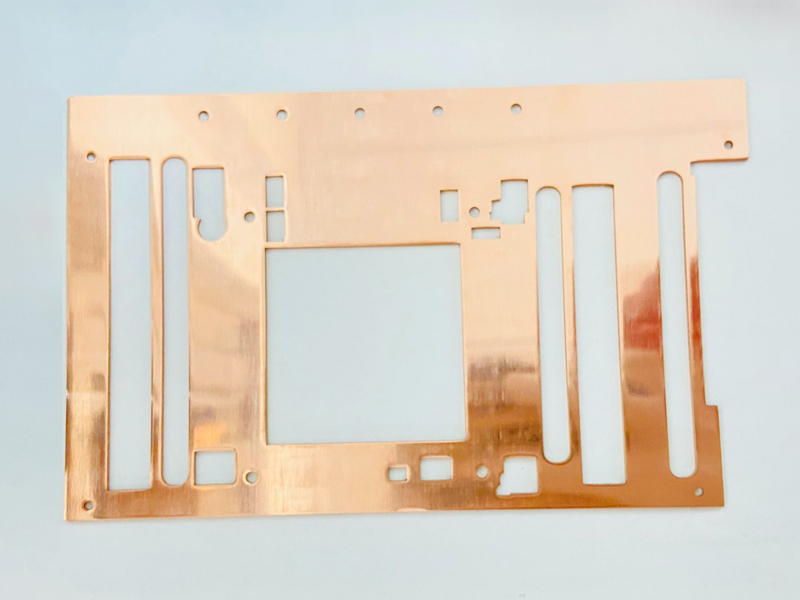

Copper Sheet Metal Fabrication

The Essential Role of Copper in Sheet Metal Fabrication

Copper sheet metal fabrication is a process that employs various copper alloys to create parts with distinct physical and chemical properties. Here's a closer look at the significance of copper in sheet metal fabrication:

Color and Appearance: Pure copper exhibits a light red color, which transforms into a purplish-red hue once a copper oxide film forms on its surface, adding to its aesthetic appeal.

Superior Conductivity: Copper is renowned for its excellent electrical and thermal conductivity, with electrical conductivity second only to silver and thermal conductivity ranking just below gold and silver.

Chemical Stability: Copper boasts impressive chemical stability and corrosion resistance, performing well in the atmosphere, fresh water, and seawater, making it suitable for a range of environmental conditions.

The Multifaceted Advantages of Utilizing Copper in Sheet Metal Fabrication

Copper's exceptional properties make it an invaluable resource in the field of sheet metal fabrication. Here's a summary of the benefits copper brings to the manufacturing table:

Superior Conductivity: Copper's thermal and electrical conductivity is among the highest of all metal materials, making it ideal for components that require efficient heat dissipation or electrical transmission.

Chemical Stability: With excellent chemical stability, copper is easy to melt and exhibits strong corrosion resistance, extending the lifespan of the parts created from it.

High Formability: Copper's high ductility translates to high formability, facilitating the fabrication process and allowing for the creation of complex shapes that would be more challenging with less malleable materials.

Good Ductility: Its ductility allows copper to withstand various cold and hot pressure processing, offering flexibility in manufacturing.

Versatility in Applications: Copper's properties make it a versatile choice for manufacturing a variety of structural parts within the machinery industry.

Despite this limitation, copper remains one of the most popular materials used in sheet metal fabrication due to the ease with which it can be worked into sheet metal parts. Copper and its alloys have properties that facilitate the production of components, making the fabrication process more manageable for manufacturers.

Copper sheet metal parts are frequently utilized in industries that demand high conductivity and corrosion resistance, such as chemical, aerospace, and automotive sectors. Whether for electrical components, heat exchangers, or decorative elements, copper's unique attributes make it a material of choice for creating high-quality, functional sheet metal parts.

Versatility in Applications: Copper's properties make it a versatile choice for manufacturing a variety of structural parts within the machinery industry.

Resistance to Processing Stresses: The metal's ability to withstand all types of cold and hot sheet metal processing ensures that copper parts can be fabricated without compromising their integrity.

Recyclability: Copper is one of the few materials that can be easily recycled and reused without a significant loss in quality, contributing to environmental sustainability and cost savings.

Cost-Effectiveness: Despite its many advantages, copper remains more affordable than many other types of sheet metal, offering a cost-efficient solution for manufacturing needs.

These benefits highlight why copper is not only a practical choice but also an effective one for sheet metal fabrication. Its combination of conductivity, formability, and affordability make it a go-to material for fabricators looking to produce high-quality, durable parts. Whether for electronics, heating and cooling, or structural applications, copper's versatility and performance are unmatched.

Popular Copper Alloys in Sheet Metal Fabrication: Copper 101 and Copper 110

In the realm of sheet metal fabrication, specific copper alloys stand out for their high purity and desirable properties. Here's a look at the two common types of copper alloys used in this field:

Copper 101: This alloy is recognized as oxygen-free copper, boasting a high purity level with 99.99% copper content. Its outstanding electrical conductivity and malleability make it a prime choice for fabricating electrical components. Copper 101 is known to work-harden at a slower rate than other metals, making it manageable during the forming process. It can also be annealed to improve its formability. Typical uses for C101 in sheet metal fabrication include grounding strips, anodes, and circuit breakers, where its excellent conductivity and ductility are highly valued.

Excellence in Copper Sheet Metal Fabrication Services

Copper sheet metal stands as an optimal choice for industrial production, offering high flexibility and durability. As a seasoned company specializing in metal machining and fabrication, LK tools provides comprehensive copper sheet metal fabrication services capable of producing copper parts in a vast array of sizes and shapes. Whether your project calls for ornamental components or functional industrial applications, we have the expertise to deliver.

Copper's exceptional corrosion resistance makes it an excellent choice for fabricating various pipes and tubes that can withstand the elements. At LK tools, we typically work with C101 and C110 copper grades, known for their high purity and conductivity. However, we are also equipped to work with other copper alloys to meet your specific material requirements.

Copper 110: Also known as Electrolytic Tough Pitch (ETP) copper, Copper 110 contains 99.90% copper and is widely regarded for its purity. This alloy is the most commonly available copper on the market and is extensively used in applications that require efficient electrical and thermal transfer. Copper 110 is commonly found in components such as heat exchanger fins and electrical switches due to its excellent thermal conductivity and electrical properties.

Both Copper 101 and Copper 110 are over 99% copper, with the remaining content being impurities. These alloys provide sheet metal fabricators with high-quality materials that are particularly suited for creating parts that require high conductivity, such as those found in electrical and thermal systems. Their high purity and specific properties make these copper alloys an indispensable resource in precision sheet metal fabrication.

ur capacity to fabricate an extensive selection of custom copper sheet metal parts includes, but is not limited to, plates, fixtures, shields, and brackets. No matter if your needs range from a single prototype to large-scale production runs, we invite you to send us your inquiry.

Copper and its alloys are favored materials for custom parts created in our machine shop due to their workability and excellent properties. LK tools's sheet metal services extend from precision laser cutting to punch pressing and tube bending, among others.

Choose LK tools for your copper sheet metal fabrication needs and experience the quality and precision that come with our dedicated service. We are committed to turning your designs into reality with the highest standards of craftsmanship and attention to detail.

Discover the Advantages of Copper Sheet Metal Fabrication with LK tools

When it comes to copper sheet metal fabrication, LK tools is a name synonymous with experience, quality, and reliability. Here's why you should choose LK tools for your fabrication needs:

Extensive Experience: With nearly two decades of experience in sheet metal fabrication, our team has honed the skills necessary to deliver superior quality in every project we undertake.

Timely Delivery: We understand the importance of deadlines and are committed to manufacturing your parts efficiently and delivering them on time, every time.

Comprehensive Capabilities: Our variety of sheet metal fabrication capabilities ensures that we can tackle projects of all types and complexities with ease.

Expert Team: Our dedicated team of skilled experts is meticulous in ensuring that every specification of your project is met with precision.

Exceptional Customer Service: At LK tools, customer satisfaction is paramount. We maintain close communication with our clients to ensure a seamless and satisfying experience from start to finish.

Quality Commitment: We are committed to upholding the highest quality of services and products, ensuring that what we provide aligns with the standards our clients expect and deserve.

Choosing LK tools for your copper sheet metal fabrication means partnering with a company that brings unparalleled expertise and dedication to your project. Contact us to discuss how we can fulfill your copper fabrication needs with the utmost professionalism and