CNC Machining Polyethylene

Precision CNC Machining of Polyethylene: Your Guide to PE Plastic

When it comes to machining versatile plastics, polyethylene (PE) stands out as a prime candidate for a range of applications. LK tools's polyethylene CNC machining services are designed to supply parts with high accuracy and quality. But what exactly is polyethylene, or PE plastic?

Polyethylene, often abbreviated as PE or referred to as polythene, is currently the most widely used plastic, particularly prevalent in the packaging industry. PE plastic is characterized by its white waxy and translucent appearance. The material is soft yet tough, lighter than water, and non-toxic, making it suitable for a variety of uses.

One of PE's notable attributes is its superior dielectric properties, making it an excellent electrical insulator. While PE exhibits low strength, hardness, and rigidity, it compensates with high ductility, impact strength, and low friction, which are beneficial for products that require durability and resistance to wear.

Understanding the Different Types of Polyethylene Plastics and Their Uses

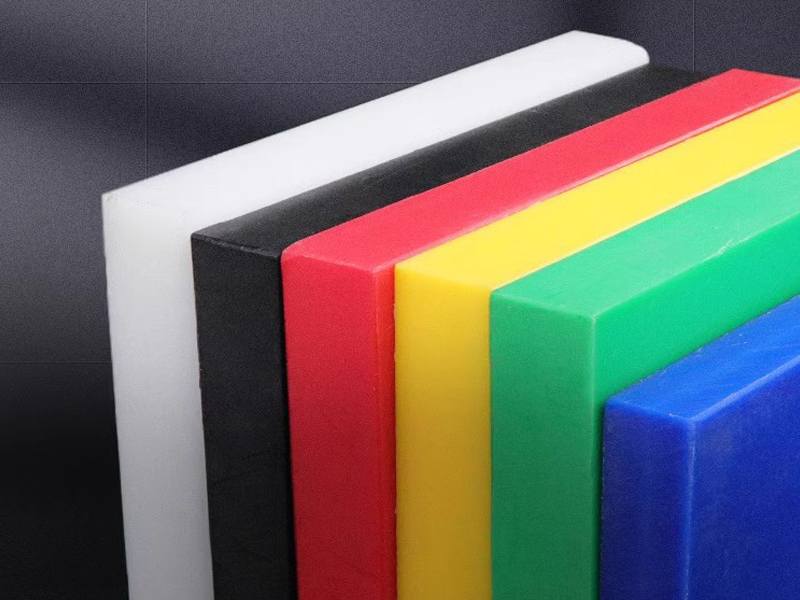

Polyethylene (PE) plastics are differentiated by their density and molecular structure, each type offering unique properties suitable for specific applications. Here's an overview of the common types of polyethylene plastics:

Low-Density Polyethylene (LDPE): Recognized by its milky white appearance, LDPE is tasteless, odorless, non-toxic, and has a waxy feel with a matte surface. With a density of 0.91 – 0.93g/cm3, it is the lightest form of polyethylene resin. LDPE is noted for its flexibility, extensibility, electrical insulation, transparency, and ease of processing. It also has a certain degree of air permeability and impressive chemical stability, being resistant to alkalis and most organic solvents.

Linear Low-Density Polyethylene (LLDPE): This non-toxic, tasteless, and odorless variant has a density ranging from 0.918 – 0.935g/cm3. LLDPE offers higher softening and melting temperatures compared to LDPE, along with enhanced strength, toughness, rigidity, heat resistance, and cold resistance. It also exhibits good environmental stress cracking resistance, impact strength, and tear strength, making it resistant to acids, alkalis, and organic solvents. LLDPE is widely utilized in industrial, agricultural, and medical sectors.

Chemical stability is another of PE's strengths; it is notably resistant to a range of chemicals at room temperature, including hydrochloric acid, hydrofluoric acid, phosphoric acid, and bases like sodium hydroxide and potassium hydroxide. However, polyethylene is vulnerable to nitric and sulfuric acids and can degrade under ultraviolet light.

The most recognized types of PE include LDPE (Low-Density Polyethylene), HDPE (High-Density Polyethylene), UHMWPE (Ultra High Molecular Weight Polyethylene), and LLDPE (Linear Low-Density Polyethylene), each with specific properties tailored to different applications.

At LK tools, we harness the various properties of PE plastics to machine parts that meet the exact needs of our clients, from simple packaging solutions to complex components requiring high precision. Contact us to learn more about how we can bring your polyethylene CNC machining projects to life with expertise and efficiency.

High-Density Polyethylene (HDPE): HDPE is a non-polar thermoplastic resin with a high degree of crystallinity, typically appearing as a white powder or granules. It is non-toxic and tasteless, with crystallinity between 80% and 90%, a softening point of 125 – 135 ℃, and a service temperature that can reach 100 ℃. HDPE boasts superior hardness, tensile strength, creep resistance, wear resistance, electrical insulation, toughness, and cold resistance compared to LDPE. It demonstrates excellent chemical stability, remaining insoluble in any organic solvent at room temperature and resistant to various acids and alkalis.

Ultrahigh Molecular Weight Polyethylene (UHMWPE): UHMWPE is a high molecular weight compound known for its challenge to process, but it offers exceptional wear resistance and self-lubrication. It's a thermoplastic engineering plastic with a linear structure and excellent comprehensive properties.

Each type of PE plastic has found its niche in various applications, from packaging and consumer goods to components in medical and industrial equipment, highlighting the adaptability and utility of these materials in modern manufacturing.

Your Go-To Manufacturer for Precision Polyethylene CNC Machined Parts

LK tools offers a comprehensive range of PE CNC machining services that cater to the unique needs of customers seeking custom polyethylene parts. Whether you require high-density, low-density, or another variant of polyethylene, Junying is equipped to produce precision machined parts with the expertise and quality that set us apart in the industry.

Versatile Material Expertise: As a trusted supplier, we have the capability to work with an extensive array of thermoplastics, including various types of polyethylene, ensuring that we can meet the diverse requirements of our clients.

Years of Machining Experience: Our wealth of experience and accumulated knowledge in CNC machining allows us to confidently produce most custom polyethylene parts to the exact specifications provided by customers.

State-of-the-Art CNC Technology: We utilize CNC Polyethylene machining as a versatile and efficient manufacturing solution, enabling us to deliver a large volume of high-quality parts. Our advanced technology ensures complex geometries are machined with high consistency and precision.

The Outstanding Advantages of Polyethylene Material in Manufacturing

Polyethylene (PE) is a widely used material in the manufacturing industry, cherished for its numerous benefits that make it suitable for a wide range of applications. Here are some of the key advantages of using polyethylene material:

High Toughness and Impact Strength: PE is known for its exceptional toughness, allowing it to withstand strong impacts and stresses without compromising its integrity.

Low Moisture Absorption: Polyethylene has a very low rate of moisture absorption, contributing to its excellent electrical insulation properties and making it suitable for applications where exposure to moisture is a concern.

Great Chemical Resistance: One of the hallmark features of PE is its resistance to a broad spectrum of chemicals, including acids, alkalis, and various solvents.

The Outstanding Advantages of Polyethylene Material in Manufacturing

Stable Across Temperatures: PE maintains its stability across a range of temperatures, performing reliably in both high and low-temperature environments.

Excellent Strength-to-Weight Ratio: Despite its lightweight nature, polyethylene offers remarkable strength, making it an efficient choice for applications requiring a high strength-to-weight ratio.

Variety of PE Variants: The diversity of PE types, including HDPE, LDPE, and UHMWPE, among others, provides manufacturers with options to choose the best variant that fits the specific requirements of their application.

These properties make polyethylene a versatile and practical choice in industries from packaging and construction to electronics and automotive manufacturing. Its combination of durability, chemical resistance, and adaptability ensures that polyethylene continues to be a go-to material for innovative and reliable solutions.

End-to-End Production Excellence: From initial design consultation to selecting the right material and through to the final stages of production, LK tools is well-equipped and skilled to ensure the best possible outcome for your project.

Located in China, LK tools is committed to providing exceptional customer service and superior CNC machined PE plastic parts that meet both domestic and international standards. Engage with us for your polyethylene machining needs and experience the quality and reliability that come with our custom manufacturing solutions.

The Premier Choice for CNC Polyethylene Machining Services

When it comes to CNC machining of polyethylene components, LK tools is an industry leader, offering a host of compelling reasons to choose our services:

Continuous Updates: We keep our clients informed throughout the production and delivery process, ensuring transparency and up-to-date communication on the progress of their parts.

Flexible Production Capacity: Whether you're looking for rapid prototypes or need to scale up to low or high volume production, LK tools has the capacity to meet your demands with agility.

Quality Assurance: Our ISO 9001 certification is a testament to our commitment to quality insurance. Along with strict quality control measures in place, we ensure that every polyethylene part we produce meets exacting standards.

State-of-the-Art Equipment: Our advanced machining centers and inspection instruments are at the forefront of technology, enabling us to achieve precision and accuracy in every project.

Extensive Experience: With decades of CNC manufacturing experience, LK tools has built a legacy of expertise in producing high-quality machined parts.

Expert Team: Our seasoned experts and well-trained operators are the backbone of our operations, dedicated to delivering optimal results in CNC polyethylene machining.

At LK tools, we are committed to providing our clients with exceptional machined components, combining our extensive experience with cutting-edge technology and skilled craftsmanship. Choose LK tools for your CNC polyethylene machining needs and partner with a team that's equipped to bring precision and quality to your projects.