Laser Cutting Services

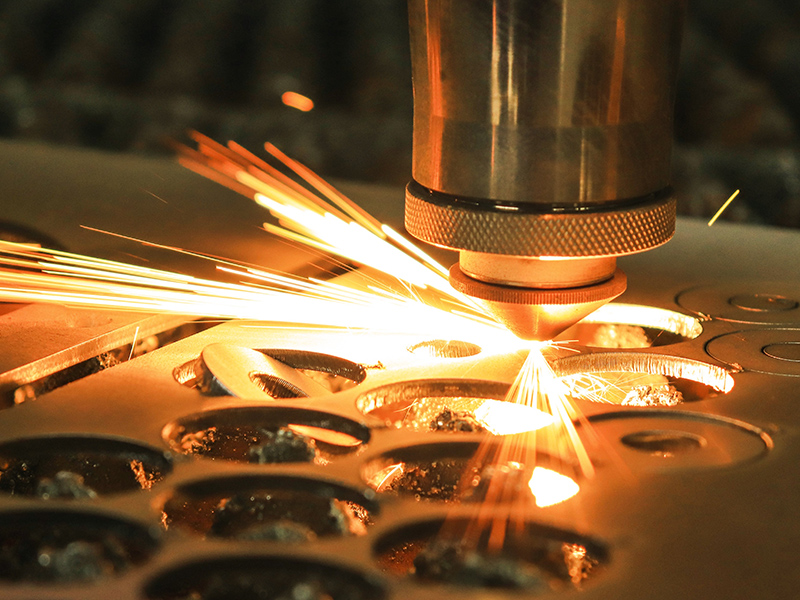

The Precision of Inline Tube Laser Cutting

Inline tube laser cutting represents a significant leap forward in metal fabrication technology. Utilizing powerful 4 kW inline fiber-optic systems, our capabilities extend to cutting a variety of shapes, including round, square, and rectangular tubes, as well as open profiles. The equipment can accommodate materials with an outer diameter of up to 6 inches, showcasing impressive versatility.

One of the standout features of inline tube laser cutting is its ability to execute angled cuts along multiple sides or edges of the material. This precision is particularly valuable when creating complex components that require a high degree of accuracy and consistency.

Cutting-Edge Multi-Axis Laser Cutting System for Complex Geometries

In the world of fabrication, the ability to cut complex three-dimensional profiles with precision is crucial for meeting the intricate demands of modern designs. Our multi-axis, 3 kW laser cutting system is specifically engineered to tackle such challenges. This advanced equipment is perfectly suited for tube laser cutting projects that not only demand tight tolerances but also involve cutouts positioned in areas that would typically necessitate additional post-bending operations, such as machining or punching.

The true value of this multi-axis system lies in its potential to streamline the manufacturing process. By accurately making complex cuts, it can significantly reduce or even eliminate the need for secondary operations. This not only simplifies the production workflow but also results in considerable cost savings by cutting down on the time and expense associated with consumable tooling.

The robustness of the operating system behind our tube laser cutting equipment cannot be overstated. It allows for the creation of intricate designs, such as slots, notches, and copes with ease. In addition, our system can produce custom hole patterns that meet the unique specifications of various projects.

The adaptability and precision of the inline tube laser cutting process make it an indispensable tool in modern manufacturing. Whether the task involves producing components for industrial machinery, architectural structures, or custom fabrication projects, our tube laser cutting services are up to the challenge, delivering clean, precise, and repeatable cuts every time.

Enhancing the efficiency of this system is the incorporation of robotic part handling and dual access loading capabilities. These features ensure that the workflow remains uninterrupted and highly efficient, allowing for quick transitions between cutting tasks and reducing downtime. The result is a seamless operation that can maintain high productivity while delivering parts with intricate profiles and precise cutouts.

Our multi-axis laser cutting technology is a game-changer for manufacturers who require a high degree of complexity in their parts. With its precision, speed, and cost-effectiveness, it stands as a formidable asset in the competitive landscape of fabrication, enabling the production of components that meet the exacting standards of industries ranging from aerospace to custom machinery.

Fiber-Optic Tube Laser Cutting: Versatile Equipment for Diverse Features

When it comes to fabricating features on the body or edges of tubular materials, fiber-optic tube laser cutting stands out as the method of choice. This advanced technique is highly suitable for crafting precise shapes – or "features" – on round, square, or rectangular tubes and pipes. For medium to high production volumes, the precision, speed, and flexibility offered by fiber-optic laser cutting are unmatched.

One of the key advantages of using a laser for these applications is its ability to cut or etch intricate shapes into metal tubes or pipes. These complex cuts can be difficult, or even impossible, to achieve with conventional machining tools such as vertical mills or drill presses. The laser cutting process, on the other hand, allows for precise and clean cuts without the physical contact or tool wear associated with traditional methods.

Versatile Material and Size Capabilities for Laser Cutting

Our laser cutting services cater to a diverse range of materials and sizes to meet the varied needs of our clients. We have the capacity to work with several types of metals, ensuring that we can handle projects across various industries with precision and efficiency.

Materials We Cut:

Steel: A reliable and sturdy material used in a variety of applications.

Stainless Steel: Known for its corrosion resistance and strength, ideal for more demanding environments.

Aluminum: Lightweight and corrosion-resistant, suitable for up to 3/8" thickness.

Copper: A highly conductive metal often used in electrical components.

Bronze: An alloy known for its toughness and wear resistance.

Brass: A versatile alloy with a bright, gold-like appearance and good corrosion resistance.

Galvanized Pipe: Coated in zinc for extra corrosion resistance.

Sizes and Shapes We Accommodate:

The laser's versatility extends beyond cutting; it can also be used for etching or engraving, adding functional or aesthetic features to the metal surface. This can be particularly useful in applications where parts require identification marks, decorative patterns, or technical specifications.

If you're looking to obtain a quick quote for your project that involves fiber-optic tube laser cutting, we invite you to submit your request through the orange prompt below. Our team is ready to provide you with a comprehensive evaluation and help bring your project to life with the efficiency and precision that only laser cutting can offer.

Round Pipe or Tube: We can process round tubing with an outer diameter (O.D.) of up to 6 inches.

Square Pipe or Tube: Our capabilities include square tubing up to 6 inches in size.

Rectangle Tube: We handle rectangular tubes also up to 6 inches.

Thin-Walled Tube: We specialize in cutting thin-walled tubing ranging from ½ inch to 4¾ inches O.D.

Flat Sheets: Our services extend to flat sheets in thicknesses from .03 inches to .80 inches, catering to a variety of applications and specifications.

Our advanced laser cutting technology allows us to deliver precise cuts and detailed fabrications on all of these materials and sizes. Whether you require components for construction, automotive, aerospace, or decorative purposes, we have the tools and expertise to meet your needs.

If you have a specific project in mind, please reach out with the details of your material and size requirements. We're here to provide you with high-quality laser cutting services tailored to your unique specifications.

The Cutting Edge: Advantages of Tube Laser Cutting

Tube laser cutting offers a suite of advantages that make it a superior choice for processing tubular materials. Among its standout benefits are its speed and efficiency, which are crucial in high-paced production environments.

Clean Edges and Reduced Finishing Time

One of the most significant advantages of tube laser cutting is the quality of the edges it produces. The cuts are exceptionally clean, which greatly reduces, or in some cases completely eliminates, the need for lengthy deburring or other finishing operations. This results in a smoother production process and a more refined final product.

Increased Production Throughput

The precision of tube laser cutting also allows for minimal part handling during the production cycle. This streamlined approach is especially beneficial when it comes to complex operations such as hole punching, drilling, slotting, notching, coping, or part

marking. By reducing the steps involved in handling and preparing materials, tube laser cutting enhances overall throughput, allowing for more parts to be processed in less time.

Advanced Machine Technology

The technological advancements in tube laser cutting machines contribute significantly to these benefits. With features such as automated loading and unloading, high-speed cutting heads, and sophisticated software controls, these machines are designed to maximize productivity and maintain high-quality standards.

For those interested in learning more about the specifics of our tube laser cutting capabilities, we encourage you to review our list of tube laser cutting machine technology utilized within our facilities. This information will provide insight into how we can support your project's requirements with the cutting-edge solutions our services offer.