CNC Turning Parts Service

Precision CNC Turning Services for Custom Earphone Cases and More

Our CNC machining services streamline the creation of custom phone cases with precision and efficiency. Here's a breakdown of our comprehensive process:

Our CNC turning services cater to the production of high-quality, custom parts, including intricate earphone cases. Here's an insight into the composition and production process of an earphone case, alongside our CNC turning capabilities:

Composition of an Earphone Case:

TPU Material: Provides the flexibility and durability needed for the main structure of the case.

PET Printing Material: Used for high-quality design prints on the case.

Printing Ink: Ensures vibrant and long-lasting designs.

Adhesive: Bonds the printed material to the TPU securely.

Production Process Overview:

Step 1: Designs are printed according to specifications.

Step 2: Silkscreening adds additional colors or effects to the print.

Step 3: Die-cutting shapes the printed material to fit the earphone case.

Step 4: The die-cut material is placed in an injection mold and formed together with TPU material.

CNC Turning Service:

Optimizing Your Designs with Our CNC Turning Guidelines

To ensure the success of your CNC turning projects, we provide a set of basic design guidelines that facilitate improved manufacturability, aesthetic quality, and efficient production timelines. Here are the key design considerations for CNC turning:

CNC Turning Dimensions (US and Metric):

Maximum Dimensions:

Diameter: Up to 3.95 in. (100.33mm)

Length: Up to 9 in. (228.6mm)

Minimum Dimensions:

Diameter: At least 0.16 in. (4.07mm)

Length: At least 0.05 in. (1.27mm)

Wall Thickness: A minimum of 0.020 in. (0.51mm) is required for structural integrity.

Our service ensures the rapid production of custom turned parts, suitable for prototyping and end-use production, with lead times as fast as 1 day.

Certifications:

We maintain ISO 9001:2015, AS9100D, and ITAR registration, emphasizing our commitment to quality and precision.

Capabilities and Applications:

Our CNC lathe with live tooling allows us to create features such as axial and radial holes, flats, grooves, and slots, expanding the range of part designs we can produce.

CNC turning is ideal for functional prototypes, end-use parts, and components with cylindrical features or detailed cut-outs.

For detailed information on our capabilities, the materials we work with, available surface finishes, and more about our CNC turning services, jump to the relevant sections on our website. Trust us for your CNC turning needs and experience the benefits of working with a leading provider of precision machining services. Contact us to get started on your project today.

Angle: Minimum allowable angle is 30°.

Tolerances: Precision tolerances of +/- 0.005 in. (0.13mm) can be consistently achieved.

Additional Notes on CNC Turning:

Small Feature Considerations: While small features are permissible, ensure that the diameter in any region is not less than 0.030 in. (0.76mm) to maintain structural integrity.

Conical Points: Sharp conical points are allowed; however, angles must be greater than 30 degrees to be machinable.

Wall Survivability: Walls thinner than 0.020 in. (0.5mm) typically cannot withstand the CNC turning process.

By adhering to these guidelines, you can optimize your designs for the CNC turning process, ensuring that your parts are not only manufacturable but also meet the desired quality and aesthetic standards. If you have questions or need further assistance with your designs, our team is here to help. Contact us for support and to learn more about how our CNC turning services can bring your concepts to life.

Selecting the Right Material for CNC Turning: Our Metal Options

At our facility, we maintain a diverse inventory of metal materials to meet the varied requirements of different industries and part applications. For your CNC turned parts, we offer a selection of metals known for their machinability and desirable properties. Here's a list of the metals available for CNC turning:

Aluminum: Renowned for its lightweight, strength, and corrosion resistance, aluminum is a versatile choice for a wide range of applications, from aerospace components to consumer goods.

Brass: With its excellent machinability and distinctive golden color, brass is often used for decorative parts, as well as components in plumbing and electrical systems.

Low Carbon Steel: Ideal for applications requiring strength and ductility, low carbon steel is a cost-effective option for a variety of engineering projects.

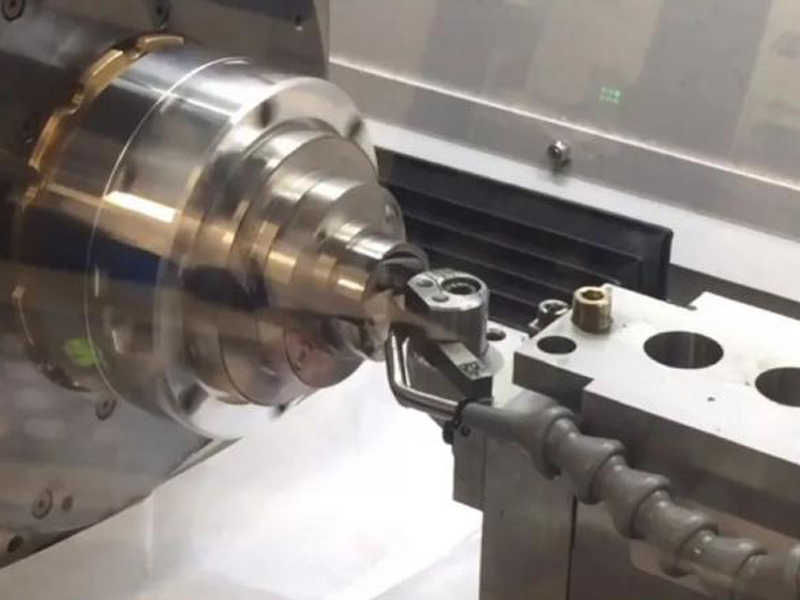

CNC Turning: A Subtractive Process for Creating Precision Parts

NC turning is a precise subtractive manufacturing technique that shapes material into finished components. Here's how the process works:

Rotational Cutting: In CNC turning, a metal rod, also known as stock, is rotated at high speeds while a cutting tool is held against it. This action removes material from the stock, gradually shaping it into the desired part.

Live Tooling Capabilities: Our CNC lathes are equipped with live tooling, allowing us to machine additional features into the rotating workpiece, such as flat surfaces and holes.

Threading Options: We offer threading capabilities for both the outside diameter (OD) and inside diameter (ID), providing versatility in the types of parts we can produce.

Steel Alloy: Steel alloys offer enhanced properties such as improved hardness or heat resistance, making them suitable for more demanding applications.

Stainless Steel: Known for its high corrosion resistance and strength, stainless steel is a premium choice for parts that must withstand harsh environments.

Titanium: This metal boasts an exceptional strength-to-weight ratio and is highly resistant to corrosion, making it ideal for aerospace, medical, and high-performance applications.

Choosing the correct material for your CNC turned parts is crucial for achieving the desired performance and durability. Our team is ready to assist you in selecting the best metal for your project, ensuring that your CNC turned parts meet your exact needs. Contact us to discuss your material requirements and take advantage of our expert CNC turning services.

Post-Machining Finishes:

As-Machined Finish: Parts can be left with an as-machined finish, displaying the tool marks that are a natural result of the turning process.

Bead Blasting: For a more uniform finish, parts can be bead blasted to remove visible tool marks and create a smooth surface.

Once the machining run is complete, all parts undergo thorough inspection to ensure they meet our high-quality standards. They are then carefully packaged and promptly shipped to our clients.

CNC turning is ideal for creating cylindrical parts and components that require high precision and a smooth finish. Whether you need a single prototype or a large batch of parts, our CNC turning process is designed to meet your exact specifications with efficiency and precision. Contact us to learn more about our CNC turning services and how we can assist with your manufacturing needs.