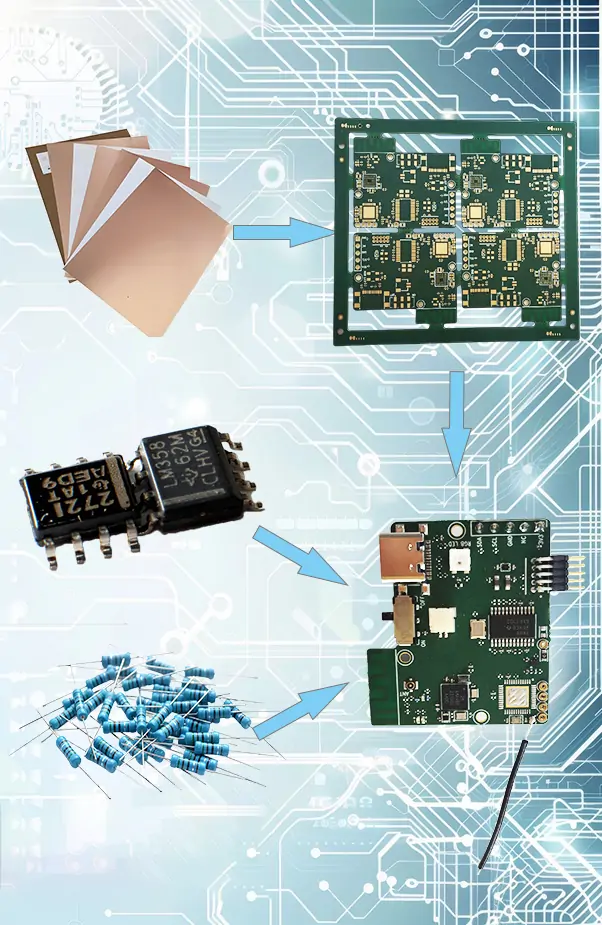

1 stop of design+pcb+pcba

1 stop of design+pcb+pcba

Finetronics (Shenzhen) Co.,Ltd set up in Yichun city, Jiangxi Province in 2010 with 600 employees in a 66,000 Square Meter factory.

We have the capability to design and manufacture various types of multilayer PCBs, HDI PCBs, high frequency PCBs, and PCBA solutions tailored to our clients' specific needs, successfully tapping into new and emerging market demands for these advanced technologies.

Our PCB and PCBA customization services include the option to print your logo, QR codes or serial number directly onto the circuit boards or packaging. This ensures that your product is not only functional but also carries your brand identity, elevating the visual appeal and professionalism of your product.

We provide tailor-made packaging options designed to protect your PCBs and PCBA assemblies during transit and storage. From anti-static bags to custom-designed boxes and packaging materials, we ensure that your products remain safe and intact, no matter the environment.

Customized Materials and Specifications

More details about Beton fabrication service of high frequency PCB

Listen to customer feedback on our high frequency pcb.

Paul Callahan(United States)

Paul Callahan(United States) Fábio Pereira de Oliveira(Brazil)

Fábio Pereira de Oliveira(Brazil) Suresha Kanakaprabha(India)

Suresha Kanakaprabha(India)

sales01@smtgo.com